Reasonable price Custom OEM Auto Brass Aluminum Plastic Precision CNC Lathe/Turning/Milling/Drilling Parts Spare Parts CNC Machining Metal Parts

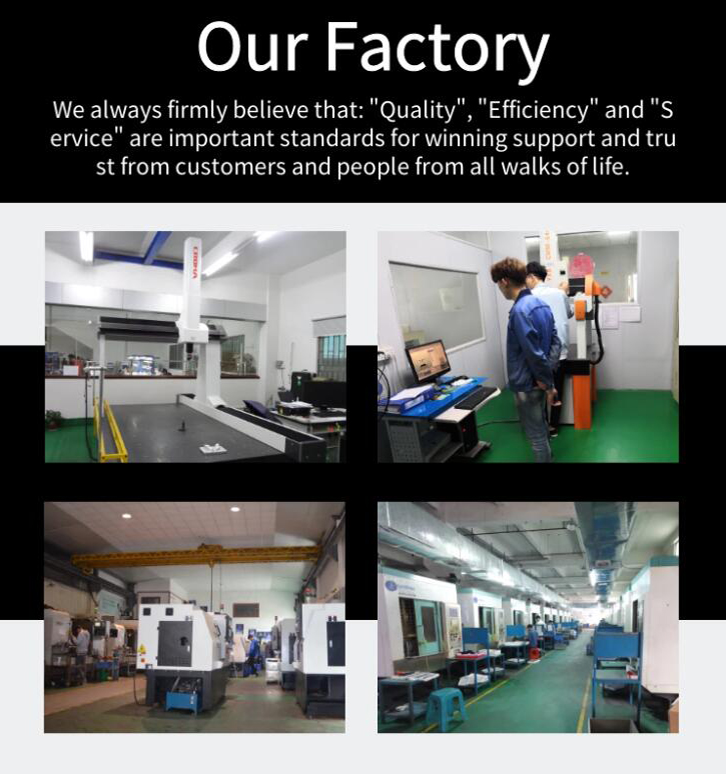

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for Reasonable price Custom OEM Auto Brass Aluminum Plastic Precision CNC Lathe/Turning/Milling/Drilling Parts Spare Parts CNC Machining Metal Parts, We’re always looking forward to forming successful business relationships with new purchasers round the earth.

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for China CNC Machining Parts and CNC Spare Parts, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

We will do our utmost to work hard to accelerate our position in the world’s leading and high-tech companies, and accelerate the rapid delivery of customized 3/4/5 Aixs Cnc processing machinery spare parts. Cnc milling anodized aluminum parts rapid prototyping.

Auto parts processing steps:

1. CNC computer Milling, through the CNC processing equipment according to the path set by the program, on the basis of the raw materials of the product, to obtain the prototype of the part.

2. It is hand-processed, after the prototype of the part comes out, the appearance of the sample will have some burrs and extra parts of the corners, the staff should use sandpaper to smooth, so that the appearance becomes smooth and refined.

3. Laser engraving, that is using laser technology to remove the paint of the sample’s appearance, so that a part of the sample is transparent.

4. Oxidation, that is, anodizing, It is the function of electrolysis. Because of the poor corrosion resistance of the oxidation formed after the treatment and the low cost of the website, it is rarely used in the process.

5. Drawing, It is to pull out a strip of fine marks on the parts’ appearance, such a treatment will make the sample feel better.

Anebon has a wide range of imported CNC Milling machines from Vertical Mills to Hi-Speed Fanuc Robodrill machines and 5-Axis Machining Centers. Anebon utilize the latest in CAD/CAM technology. Our Master CAM Software enables us to design and simulate 2D/3D models & components.

Reasonable price Custom OEM Auto Brass Aluminum Plastic Precision CNC Lathe/Turning/Milling/Drilling Parts Spare Parts CNC Machining Metal Parts Related Video: