Quality Control

Quality Control Solutions

Thorough inspections and accurate record-keeping guarantee that all parts are shipped only after careful assessment. We aim to provide the best experience with Anebon from the beginning to the end of every order with your reliable CNC machining manufacturer.

We take pride in being a trusted part of our customers’ supply chain by delivering parts precisely machined to their specifications. Our fast, innovative, responsive, and friendly approach is evident in every part we produce and every customer we serve. Order custom CNC machining parts today with Anebon.

Production Standards

Quality Assurance

Production Workflow

Measurement Instruments

Quality Enhancement

Anebon Manufacturing Standards of CNC Machining Services

- For dimensional features such as length, width, height, and diameter, as well as location features including position, concentricity, and symmetry, tolerances of ±0.005” for metals or ±0.010mm for plastics and composites are enforced according to ISO 2768 unless otherwise specified.

- Sharp edges will be uniformly broken and deburred during standard processing. Any critical edges that must remain sharp should be explicitly identified on the technical drawing. Anebon, a leading 3D printing parts manufacturer, is prepared to assist with your requirements.

- The required surface finish after machining is 125 Ra or smoother. Marks from machine tool paths may appear as swirl-like patterns.

- Machined surfaces on clear or transparent plastics will present a matte finish or exhibit translucent swirl markings. Bead blasting imparts a frosted texture to clear plastic components.

- For orientation characteristics such as parallelism and perpendicularity, as well as form features including cylindricity, flatness, circularity, and straightness, the tolerance standards outlined in the table below will be applied.

Limits for nominal size |

Plastics (ISO 2768- m) |

Metals (ISO 2768- f) |

|---|---|---|

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.1mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.2mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.3mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.5mm |

| Over 2000mm to 4000mm | ±2mm | - |

| All parts are deburred. Tightest achievable tolerance is +/-0.01mm and is dependent on part geometry. | ||

Manufacturing Standards of Sheet Metal Fabrication Services

- Anebon machining workshop possesses the expertise and necessary sheet metal fabrication capabilities to turn your concept into reality. We offer outstanding metal stamping services.

- Our offerings include precise laser cutting with tight tolerances and a broad thickness spectrum, advanced bending techniques, and various surface finishing treatments. No other sheet metal manufacturer can surpass our quality and service.

Dimension Detail |

Tolerance |

| Edge to edge, single surface | +/- 0.005 inch |

| Edge to hole, single surface | +/- 0.005 inch |

| Hole to hole, single surface | +/- 0.005 inch |

| Bend to edge / hole, single surface | +/- 0.010 inch |

| Edge to feature, multiple surface | +/- 0.030 inch |

| Over formed part, multiple surface | +/- 0.030 inch |

| Bend angle | +/- 1° |

|

By default, sharp edges will be broken and deburred. For any critical edges that must be left sharp, please note and specify in your drawing. |

|

Anebon Die Casting Manufacturing Standards

Anebon die casting workshop has the expertise and advanced equipment to deliver precise and high-quality die casting components. We provide excellent casting services with tight dimensional control, surface finish, and material integrity.

Our capabilities include fine feature definition, complex geometries, and a wide range of alloys. No other die casting manufacturer can exceed our commitment to quality and customer satisfaction.

| Dimension Detail | Tolerance |

|---|---|

| Linear dimension | +/- 0.05 mm |

| Hole diameter | +/- 0.05 mm |

| Hole position | +/- 0.10 mm |

| Wall thickness | +/- 0.10 mm |

| Angular dimension | +/- 1° |

| Surface finish (Ra) | 3.2 μm or better |

| Porosity | Less than 2% surface area |

All parts are deburred and cleaned. Critical sharp edges must be specified in the drawing to be preserved. Surface defects due to mold wear or casting process are controlled to be minimal and visually acceptable.

Pre-production

Drawing Preparation

Our skilled engineers and technicians are capable of producing products based on your drawings or samples and specific requirements. This process involves evaluating key aspects such as material, surface finish, design, manufacturing process, and other details in your 2D and 3D drawings.

Material Verification

Material certificates and test reports can be provided upon request. We utilize standard tools and techniques to examine chemical composition, physical characteristics, metallographic structure, and mechanical properties.

In Production

On-Site Inspection System

In precision machining, it is essential that materials remain correctly positioned at all times. Our on-site inspection system automatically checks positions and makes necessary adjustments. This system helps detect and resolve issues early, reducing both costs and production time.

In-Process Quality Control

At Anebon precision machining facility, we strictly adhere to ISO 9001:2015 standards. Our quality control team performs regular inspections on all components every two hours during production, minimizing the risk of defects.

Before Delivery Inspection

Comprehensive Dimensional Inspection Report

The inspection report serves as the outcome of the quality evaluation of products and equipment and acts as a benchmark for the product quality system. For every order, we can provide a complete dimensional inspection report upon request. This report covers aspects such as part quantity, key dimensions, threads and tolerances, thicknesses and depths, and overall part appearance.

Packaging

Delivering parts of the highest quality is our priority. Understanding the uncertainties of logistics, we take extensive measures to minimize risks during packaging. Our packaging process includes four layers of protection: 1. wrapping paper, 2. EPE, 3. foam, and 4. paper or wooden boxes, ensuring that we supply you with parts that are both high quality and visually pristine.

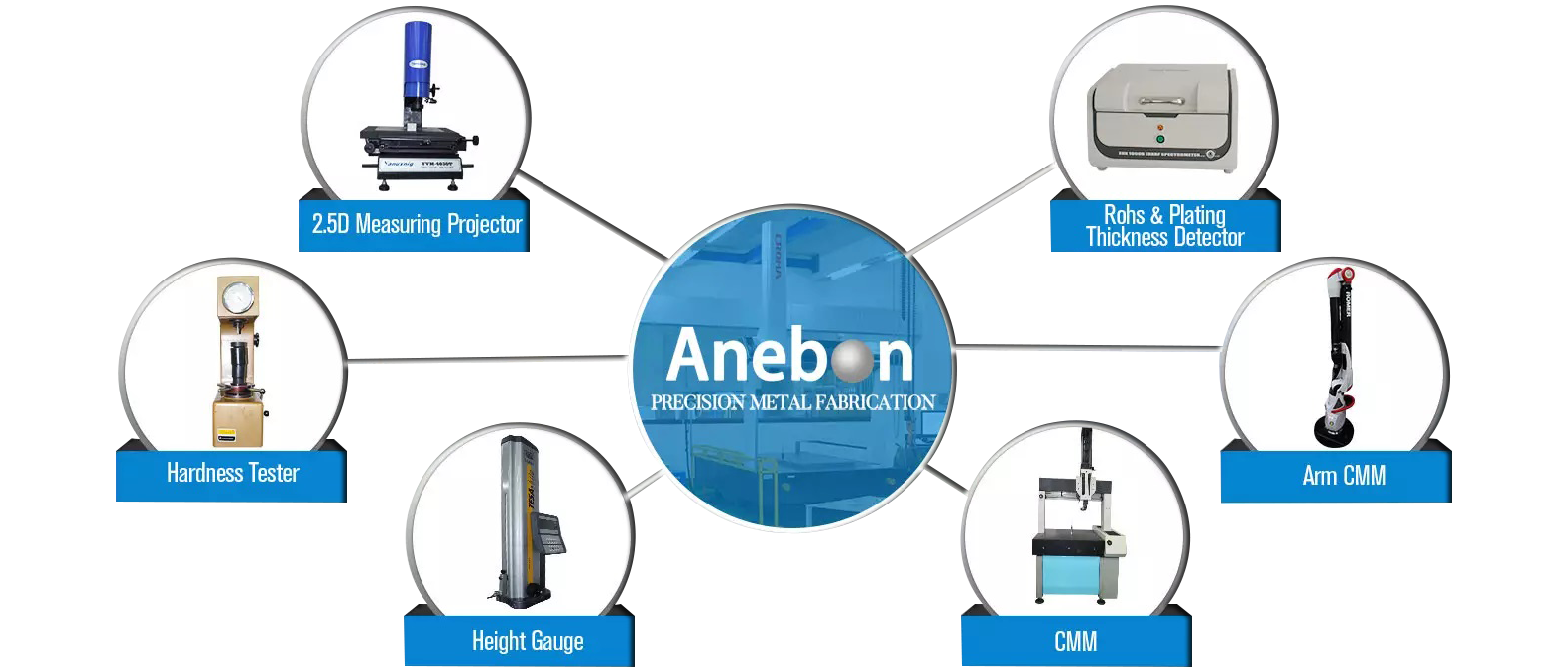

Quality Inspection Equipment

At ANEBON, we are led by an industry-experienced QC Manager and utilize state-of-the-art quality control equipment and facilities. This ensures that we consistently produce superior high-quality precision parts. We maintain a strong track record of high supplier ratings for quality through the use of the following inspection equipment:

CNC Machining Services with Certification

Our CNC machining capabilities are fully certified and comply with several internationally recognized standards to ensure quality, safety, and environmental responsibility. We adhere to ISO 9001, which guarantees that our quality management systems meet rigorous requirements for consistent product excellence. Additionally, our processes comply with RoHS and REACH regulations, confirming that our materials and manufacturing practices are free from hazardous substances and environmentally safe. Furthermore, we maintain certification under ISO 14001, demonstrating our commitment to effective environmental management and sustainable manufacturing practices throughout our operations.

Our ISO9001 & ISO14001 Certificate