When tightening bolts and nuts, should you use flat washers or spring washers?

Many people want to save flat washers or spring washers in order to save costs. In fact, flat washers and spring washers each play an indispensable role in the use of bolts. Today we will introduce to you flat pads and spring pads.

Left flat pad, right spring pad

A flat washer is a circular metal disk with a hole in the center. It is usually made by punching it out of an iron plate. Do you know how to properly use a flat washer and what its specific function is?A flat washer is a circular metal disk with a hole in the center. It is usually made by punching it out of an iron plate. Do you know how to properly use a flat washer and what its specific function is?

Flat washers are commonly used to prevent bolts and nuts from locking. They are used wherever fasteners are used. But how do you choose the right flat washer for your needs?

Firstly, it’s important to note that flat washers are a type of washer that is used to increase the contact area between screws and large equipment to ensure a tight seal. When using flat washers, it’s often best to use them in conjunction with nuts.

When storing flat washers, it’s important to ensure that they possess the necessary characteristics to provide an effective seal. Here are some key points to remember:

1. When working in harsh environments, choose flat washers that are designed to withstand extreme temperatures and pressure, to prevent leakage from occurring.

2. When attaching the flat washer to the contact surface, ensure that the sealing performance is optimal to guarantee a perfect seal.

3. The flat washer must have a good anti-wrinkle ability under pressure and temperature changes. This will prevent damage to the screws and the occurrence of air leaks.

4. Avoid contamination when using flat washers.

5. One of the biggest advantages of using a flat washer is that it makes disassembly easy.

6. Always ensure that the flat washer is used under normal temperatures.

To get the most out of your flat washers, choose ones that are dip-plated with anti-rust and anti-corrosion materials. This will not only save you time and effort but also enhance the effectiveness of the flat washer.

When selecting flat washers for use with bolts and nuts, there are several factors to consider.

Firstly, it is important to pay attention to the problem of electrochemical corrosion that can occur when different metals come into contact. Therefore, the material of the flat washer should generally be the same as the material of the connected parts, such as steel, alloy steel, stainless steel, aluminum alloy, etc. In cases where electrical conductivity is required, copper and copper alloys can be used.

Secondly, the inner diameter of the flat washer should be selected based on the larger value of the thread or screw diameter. However, if the material to be connected is soft (such as composite materials) or the outer diameter matches the spring washer, the larger value should be selected.

Thirdly, if you choose to place a W washer under the bolt or screw head, it is important to avoid interference between the fillet under the head and the washer. To achieve this, you can choose a flat washer with an inner hole chamfer.

Fourthly, steel washers should be used for important bolts with larger diameters or to increase resistance to extrusion. Steel washers should also be used for tension bolt or tension-shear composite bolt connections.

Finally, special gaskets are used in parts with special requirements. For example, copper gaskets can be used if conductivity is required, and sealing washers can be used if air tightness is required.

The primary function of a flat pad is to increase the contact area between the screw and the machine. Additionally, it helps eliminate any damage to the machine’s surface caused by the spring pad while removing screws. When using the flat pad, it should be placed next to the surface of the machine and the spring pad should be placed between the flat pad and the nut. The flat pad increases the stress-bearing surface of the screw while the spring pad plays a role in providing some buffering and protection against force to prevent screws from loosening. However, flat pads can also be used as sacrificial pads.

The flat pad is often used as a supplementary pad or a flat pressure pad. Its advantages include protecting cnc components from damage and reducing the pressure between the nut and the equipment, thus playing a protective role. However, flat washers cannot play an anti-seismic role and also have no anti-loosening effect.The function of a flat pad:

1. Increase the contact area between the screw and the machine.

2. Eliminate damage to the surface of the machine caused by the spring pad when removing screws. When using, it must be a spring pad and a flat pad; the flat pad is next to the surface of the machine, and the spring pad is between the flat pad and the nut. The flat pad is to increase the stress-bearing surface of the screw. In order to prevent the screws from loosening, the spring pads play a certain amount of buffering and protection when force is applied. However, flat pads can be used as sacrificial pads.

3. But it is more often used as a supplementary pad or a flat pressure pad.

Advantage:

① By increasing the contact area, components can be protected from damage;

② increasing the contact area reduces the pressure between the nut and the equipment, thus playing a protective role.

Shortcoming:

①Flat washers cannot play an anti-seismic role;

②Flat washers also have no anti-loosening effect.

The spring washer has several functions.

Firstly, it provides an elastic force to the nut after it has been tightened. This force resists the nut and prevents it from falling off easily, thereby increasing the friction between the nut and the bolt.

Secondly, flat washers are generally not used when spring washers are used, unless they are needed to protect the surface of fasteners and mounting surfaces. Spring washers are usually used in connectors, and they have a soft and a hard and brittle side. The main purpose of these washers is to increase the contact area, disperse pressure, and prevent the soft washer from being crushed.

Spring washers have several advantages.

Firstly, they have a good anti-loosening effect.

Secondly, they have a good anti-seismic effect.

Thirdly, they are easy to install and have a low manufacturing cost. However, spring washers are greatly affected by the materials used and the manufacturing process. If the materials are not good or the heat treatment is not done correctly, cracking may occur. Therefore, it is essential to choose a reliable manufacturer.

When dealing with loads that are relatively small and not subject to vibration, you should use flat pads.

However, when the load is relatively large and prone to vibration, a combination of flat pads and elastic pads is necessary. Spring washers are typically not used alone, but in conjunction with other pads. In practice, flat pads and spring pads are often matched with each other and used together, resulting in benefits such as parts protection, prevention of nut loosening, and vibration reduction. This makes it an excellent choice for many applications.

Flat washer combination screws are one of the many types of fasteners used in cars.

They are widely used due to their versatility and functionality. The main functions of flat gaskets in assembly are:

1. Providing a bearing surface: When the bearing surface of the bolt or nut is not enough to fully cover the connected parts, the gasket can provide a larger load-bearing surface.

2. Reducing pressure on the supporting surface: When the bearing surface area is too small, or the bearing surface pressure is too high, the gasket can reduce the bearing surface pressure or make it more uniform.

3. Stabilizing the friction coefficient of the supporting surface: When the flatness of the supporting surface of the connected cnc parts is poor, such as with stamping parts, it becomes sensitive to a seizure caused by local contact, resulting in an increase in the friction coefficient of the supporting surface. The gasket can stabilize the friction coefficient of the supporting surface.

4. Protecting the supporting surface: When tightening bolts or nuts, there is a risk of scratching the surface of the connected parts. The gasket has the function of protecting the supporting surface.

2. Failure modes of flat washer combination bolts

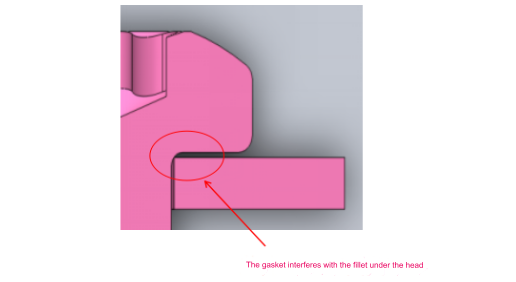

Failure mode of flat washer combination bolts–interference between the gasket and the lower fillet of the bolt head

1) Failure phenomenon

One of the key issues that can arise when using flat washer combination bolts is interference between the gasket and the lower fillet of the bolt head. This can cause abnormal torque and poor rotation of the gasket during assembly.

The interference between the gasket and the lower fillet of the bolt head is most easily identified by an obvious gap between the gasket and the lower bearing surface of the bolt head. This can result in improper fit of the bolt and gasket when the bolt is tightened.

2) Cause of failure

One possible cause of interference when combining a bolt gasket and the lower fillet of the bolt head is that the lower fillet of the bolt head may be too large or the internal aperture design of the gasket may be too small or unreasonable. This results in interference after the gasket and bolt are combined.

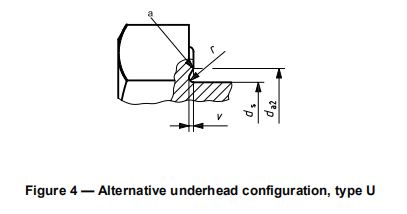

3) Improvement measures

To minimize the chance of interference when combining the bolt and gasket, it’s recommended to follow the ISO 10644 standard and use a concave design underneath the bolt head, known as type U. This will help avoid any issues that may arise from having an excessive fillet under the bolt head or a small gasket aperture.

Anebon’s goal is to understand excellent disfigurement from the manufacturing and supply the top support to domestic and abroad clients wholeheartedly for 2022 High-quality Stainless Steel Aluminum High Precision Custom Made CNC Turning Milling Machining Spare Parts for Aerospace; in order to expand our international market, Anebon mainly supplies our oversea customers Top quality performance mechanical parts, milled parts and CNC turning service.

China wholesale China Machinery Parts and CNC Machining Service, Anebon upholds the spirit of “innovation, harmony, teamwork and sharing, trials, pragmatic progress.” Give us a chance, and we will be going to prove our capability. With your kind help, Anebon believes that we can create a bright future together.