- Home

- News

- The Definitive Guide Revealed: The Comprehensive Encyclopedia of Materials Surface Treatment

The Definitive Guide Revealed: The Comprehensive Encyclopedia of Materials Surface Treatment

As a member of the industry, do you really understand the difference between different surface treatments for various materials?

There are various normal surface treatment techniques, including but not limited to:

Coating: Applying a thin layer of material (such as paint, enamel, or metal) to protect the surface, improve aesthetics, prevent corrosion, or enhance specific functionalities.

Plating: Electroplating involves depositing a thin layer of metal onto the surface of a substrate to improve corrosion resistance, conductivity, or appearance.

Heat treatment: Applying controlled heat and cooling processes to alter the microstructure and properties of metals, such as improving hardness, strength, or ductility.

Surface cleaning and preparation: Removing impurities, contaminants, or oxidation layers from the surface to ensure proper adhesion and bonding of coatings or other surface treatments.

Surface modification: Techniques like ion implantation, surface alloying, or laser treatment are used to alter the composition or structure of the surface to enhance properties like hardness, wear resistance, or chemical inertness.

Surface texturing: Creating specific patterns, grooves, or textures on the surface to improve grip, reduce friction, or enhance aesthetic appearances.

Definition:

Surface treatment is the process of creating a layer of surface material on a base with different mechanical, physical, and chemical properties.

Purpose:

Surface treatment is often done to improve the functionality of a product, such as corrosion resistance, durability, or decoration. Surface treatment is done by mechanical grinding, surface heat treatments, surface spraying, and chemical treatment. Surface treatment involves cleaning, sweeping, deburring, degreasing, and descaling the surface of a workpiece.

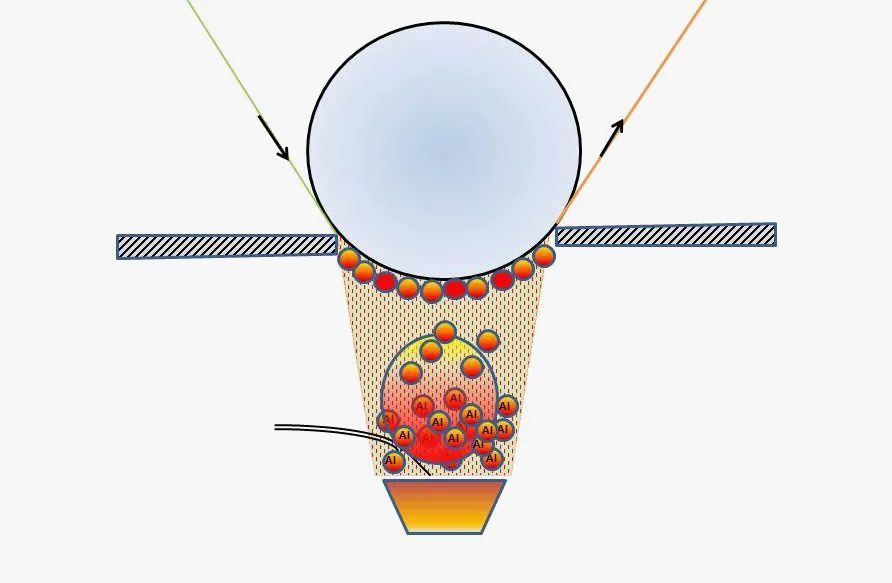

01. Vacuum plating

—— Vacuum Metalizing ——

Vacuum plating occurs as a result of a physical process. In vacuum, argon is injected and then hits the target. The target is then separated into molecules which are adsorbent by conductive goods, creating a uniform, smooth imitation metal layer.

Applicable materials:

1. Vacuum plating is possible on a wide range of materials including metals, composites, ceramics, glass, and soft and hard plastics. Aluminum is the most common electroplating surface treatment, followed by copper and silver.

2. Natural materials cannot be vacuum plated because their moisture will interfere with the vacuum environment.

Cost of process:

The labor costs are quite high in vacuum plating because the workpiece has to be sprayed and then loaded, unloaded, and resprayed. It also depends on how complex and large the workpiece is.

Environmental impact:

Vacuum Electroplating is similar to spraying in terms of its environmental impact.

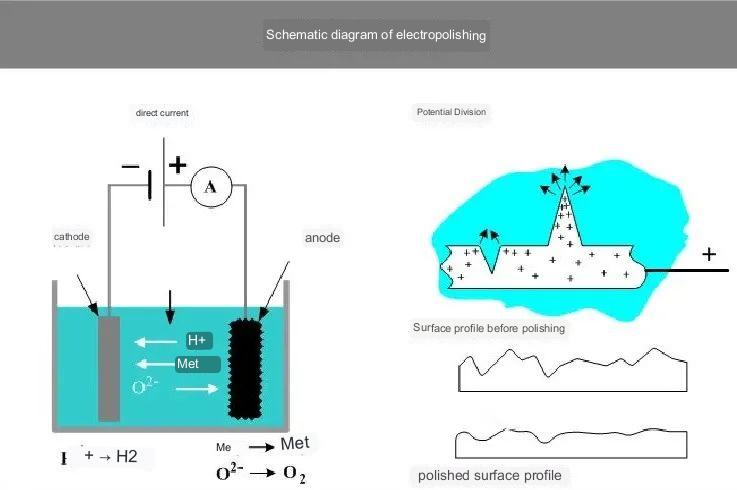

02. Electropolishing

—— Electropolishing ——

Electropolishing is an electrochemical process in which atoms of a workpiece immersed in an electrolyte are converted into ions and removed from the surface due to the passage of an electric current, thereby achieving the effect of removing fine burrs and increasing the brightness of the workpiece surface.

Applicable materials:

1. Most metals can be electrolytically polished, among which the surface polishing of stainless steel is most commonly used (especially for austenitic nuclear grade stainless steel).

2. Different materials cannot be electropolished at the same time, or even placed in the same electrolytic solvent.

Process cost:

The whole process of electrolytic polishing is basically completed automatically, so the labor cost is very low. Environmental impact: Electrolytic polishing uses less harmful chemicals. The whole process requires a small amount of water and is easy to operate. In addition, it can prolong the properties of stainless steel and delay corrosion of stainless steel.

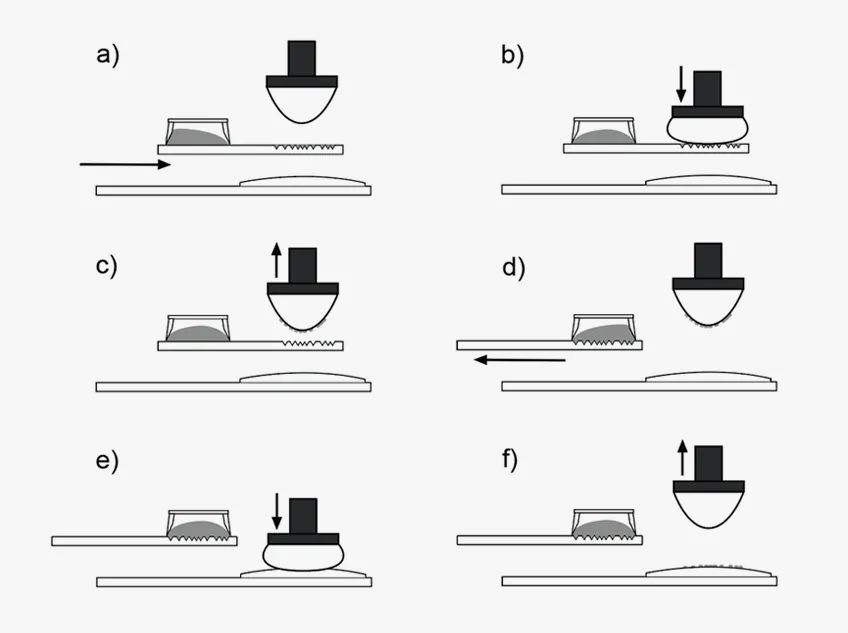

03. Pad printing process

——Pad Printing——

Being able to print text, graphics and images on the surface of irregular shaped objects is now becoming an important special printing.

Applicable materials:

Pad printing can be used for almost all materials, except materials softer than silicone pads, such as PTFE.

Process cost:

low mold cost and low labor cost.

Environmental impact: Since this process is limited to soluble inks (which contain harmful chemicals), it has a high environmental impact.

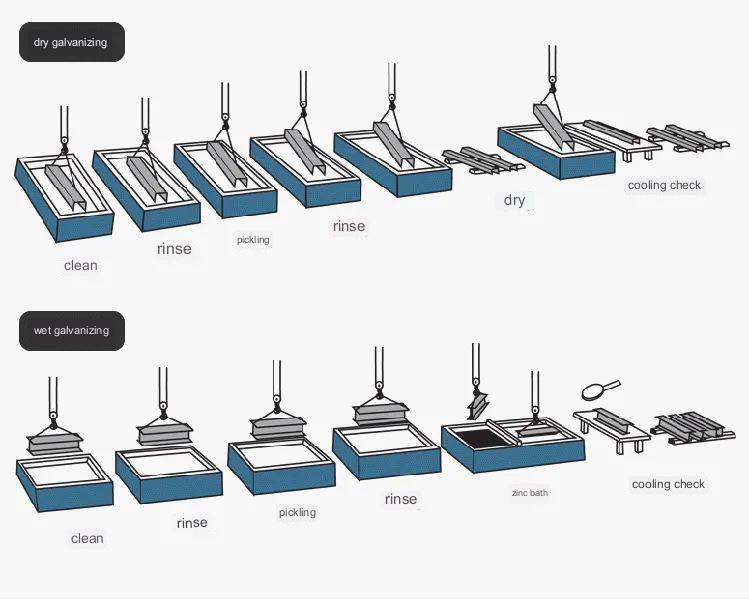

04. Galvanizing process

—- Galvanizing —-

Surface treatment that applies a thin layer of zinc to the surface of alloy steel materials. This is done for aesthetics, and also has anti-rust properties. The zinc coating on the surface acts as an electrochemical protection layer to prevent metal corrosion. Hot-dip galvanizing is the main method used.

Applicable materials:

Galvanizing is a surface treatment for steel and iron only.

Process cost:

No mold cost. Short cycle/medium labour cost. The surface quality of the piece is largely dependent on the manual surface preparation before galvanizing.

The galvanizing process has a positive impact on the environment. It increases the life expectancy of cnc milled parts from 40 to 100 years, and it prevents rusting and corrosion. The galvanized piece can also be returned to its galvanizing tank when it has reached the end of its useful life. This will produce no chemical or physical waste.

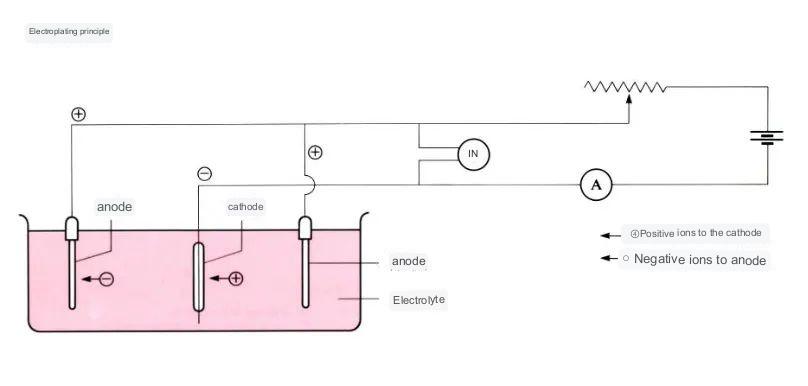

05. Electroplating Process

—- Electroplating —-

Electroplating is the process of applying a thin layer of metal to parts using electrolysis. This helps to improve corrosion resistance, wear resistance, conductivity and aesthetics. Many coins have their outer layers electroplated. .

Applicable materials:

1. Electroplating is possible on most metals, but the purity and efficiency of plating varies. These include tin and nickel.

2. ABS is the most common plastic used for electroplating.

3. Nickel is toxic and irritating to the skin. It cannot be used in products that are electroplated.

Process cost:

No mould cost, but fixtures are needed to fix the parts. Time cost is dependent on metal type and temperature. Labor cost (medium high) depends on specific plating parts. Silverware and jewelry plating require highly skilled workers due to its high demands on appearance and durability.

Environmental impact:

Electroplating uses a large number toxic substances, which require professional extraction and diversion to minimize environmental impact.

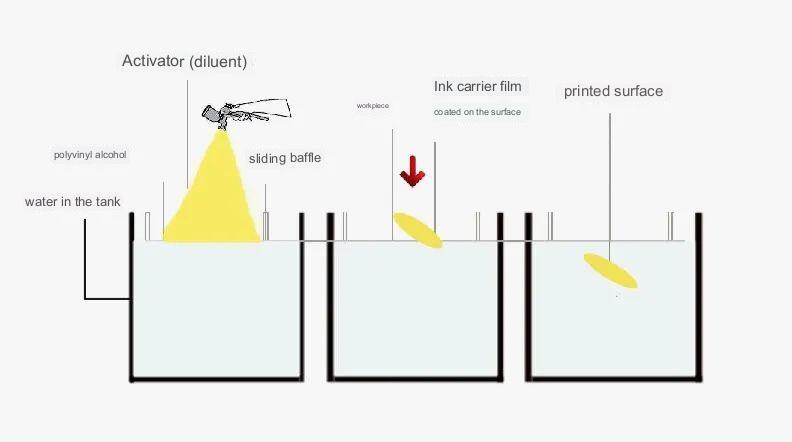

06. Water Transfer Printing

—- Hydro Transfer Printing —-

Water pressure is used to transfer the pattern of color onto the surface three-dimensional products. Water transfer printing has become more popular as people have higher expectations for packaging and surface decoration.

Applicable materials:

Water transfer printing is possible on all hard materials. Materials suitable for spraying are also suitable for this type of printing. Injection molded and cnc metal turning parts are the most common.

Cost of the process: While there is no mold, multiple products must be water-transferred simultaneously using fixtures. The time required per cycle does not usually exceed 10 minutes.

Water transfer printing is more environmentally friendly than product spraying because it applies the printing paint to a greater extent, thus reducing waste leakage.

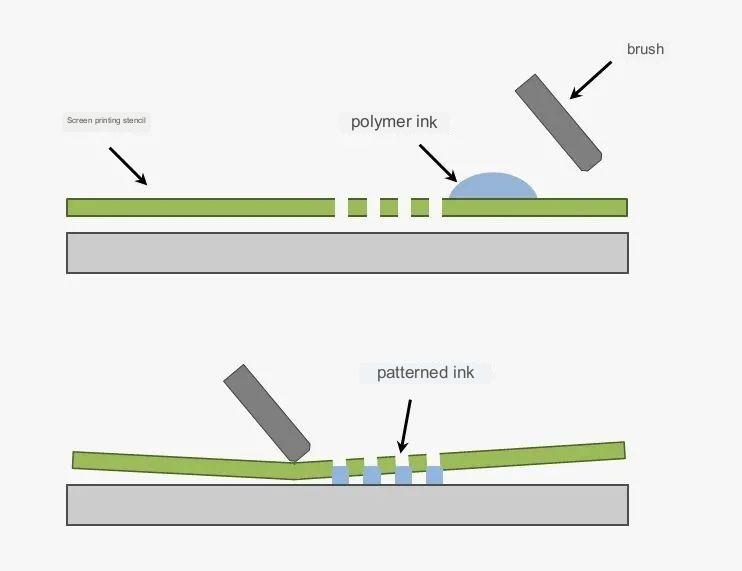

07. Screen Printing

—- Screen Printing —-

The ink is transferred through the mesh on the graphic part to the substrate by extrusion. This produces the exact same graphic as that of the original. The screen printing equipment is easy to use, simple to make plates and print, and low-cost.

Printing materials that are commonly used include color oil paintings and posters, business cards and bound covers.

Applicable materials:

Screen printing can be done on almost any material, including ceramics, glass, ceramics and metal.

Process cost:

Mold cost is low but still dependent on the number colors because each color plate needs to be made separately. The labor costs are high when printing in multi-color.

Environmental impact:

Screen printing inks with light colors have a low impact on the environment. However, inks that contain formaldehyde and PVC are harmful chemicals and must be recycled or disposed off in a timely manner to avoid water pollution.

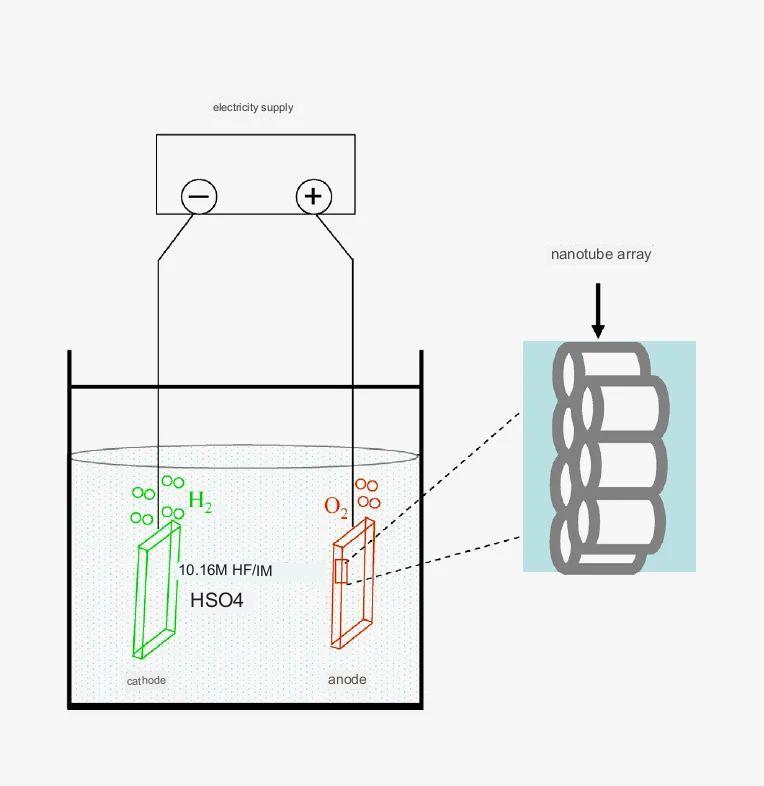

08. Anodizing

—— Anodic Oxidation ——

The anodic oxidation of aluminum is mainly based on the electrochemical principle to form a layer of Al2O3 (aluminum oxide) film on the surface of aluminum and aluminum alloy. This layer of oxide film has special characteristics such as protection, decoration, insulation, and wear resistance.

Applicable materials:

Aluminum, aluminum alloy and other cnc machining aluminum parts

Process cost: In the production process, the consumption of water and electricity is quite large, especially in the oxidation process. The heat consumption of the machine itself needs to be continuously cooled by circulating water, and the power consumption per ton is often around 1000 degrees.

Environmental impact:

Anodizing is not outstanding in terms of energy efficiency, while in the production of aluminum electrolysis, the anode effect also produces gases that have damaging side effects on the atmospheric ozone layer.

09. Metal wire drawing

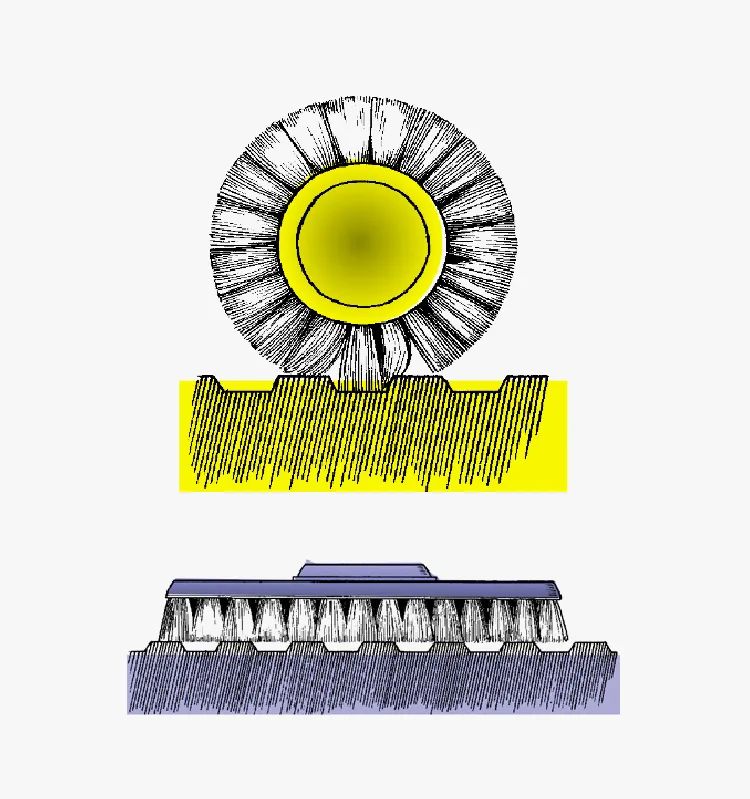

—— Metal Wired ——

It is a surface treatment method that forms lines on the surface of the workpiece by grinding the product to achieve a decorative effect. According to the different textures after wire drawing, it can be divided into: straight wire drawing, chaotic wire drawing, corrugated, and swirling.

Applicable materials:

Almost all metal materials can use metal wire drawing process.

10. In-mold Decoration

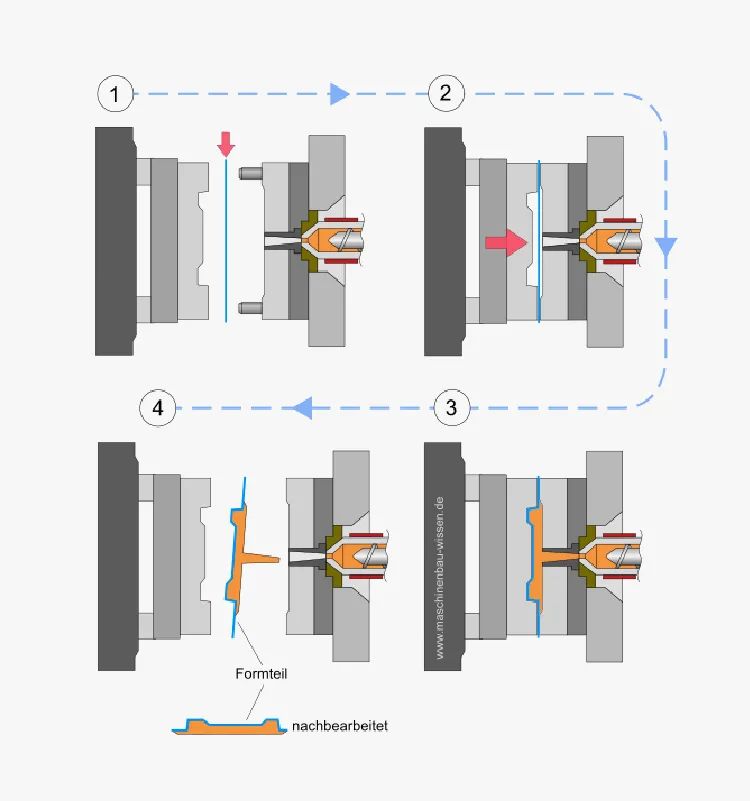

—- In-Mold Decoration-IMD —-

This molding method involves inserting the pattern-printed metal diaphragm in the metal mould, injecting the resin into the mold, joining the diaphragm together, and integrating the resin and pattern-printed metal diaphragm to form a final product.

Applicable material:

Plastic surface

Process cost:

Only need to open one set of molds. This can reduce costs and labor hours, High-automatic Production, Simplified Manufacturing Process, One-Time Injection Molding Method, and achieve both molding and decorating at the same.

Environmental impact:

The technology is environmentally friendly and green, and avoids the pollution that traditional electroplating and painting causes.

Process cost:

The process method is simple, the equipment is simple, the material consumption is very little, the cost is relatively low, and the economic benefit is high.

Environmental impact:

Pure metal products, no paint or any chemical substances on the surface, 600 degrees high temperature does not burn, does not produce toxic gases, meets fire protection and environmental protection requirements.

Keep improving, in order to ensure that the product is that is in line with standards of the market and customers. Anebon has a quality control system in place to ensure high-quality 2022 hot sales Parts for ABS Plastic Drilling CNC Machining Turning Part Service, Trust Anebon and you’ll gain many more benefits. Please take the time to reach us for further information, Anebon guarantees you our full attention throughout the day.

Auto spare parts of high-quality milling parts, steel turned parts manufactured by China Anebon. The products from Anebon have gained increasing recognition from clients abroad and have established a long-term and mutually beneficial relationships with Anebon. Anebon will offer the highest quality service to each customer. We warmly welcome new friends to join with Anebon and create mutual benefits.