Master the Art of Mechanical Design: Essential Knowledge Points for Engineers

How much do you know about mechanical design?

Mechanical design is a branch of engineering which uses various principles and techniques to design, analyze and optimize mechanical systems and components. Mechanical design includes understanding the intended purpose of a component or system, choosing appropriate materials, taking into account various factors, such as stresses and strains and forces, and ensuring reliable and efficient function.

Mechanical design includes machine design, structural design, mechanism design and product design. Product design is concerned with the design of physical products such as consumer goods, industrial equipment and other tangibles. Machine design, on the other hand, focuses on creating machines like engines, turbines and manufacturing equipment. Mechanism design is concerned with designing mechanisms that convert inputs to desired outputs. Structural design is the final step. It involves the analysis and design of structures such as bridges, buildings, and frames for their strength, stability, safety, and durability.

What is the specific design process like?

The design process usually involves various steps, such as the identification of a problem research and analysis, idea generation and detailed design and prototyping, as well as testing and the elaboration. In these phases engineers employ different techniques and tools like computer-aided design (CAD) software, finite element analysis (FEA) and simulation to verify and improve the design.

What factors do designers need to consider?

Mechanical design usually incorporates elements like manufacturability, ergonomics, cost-efficiency as well as sustainability. Engineers try to develop models that are not just practical and efficient however, they also have to consider the user’s demands, environmental impact and economic limitations.

It is important to remember that the field of mechanical design an extensive and continuously evolving field with new materials, technologies and methods being constantly developed. Thus, mechanical designers have to continually refresh their skills and knowledge to remain in the forefront of technological advancement.

The following are the knowledge points about mechanical design collected and organized by Anebon’s engineering team to share with colleagues.

1. The causes of failure in mechanical components is: general fracture or excessive residual deformation surface damage to precision turned components (corrosion wear, friction fatigue and wear) Failure due to the effects of normal working conditions.

2. Design components must be able to meet: requirements for avoiding failure within the specified timeframe (strength or stiffness, time) and the requirements for structural processes, economical requirements, low quality requirements, and requirements for reliability.

3. Part design criteria include Strength criteria, stiffness criteria life criteria, criteria for vibration stability and reliability standards.

4. Part design methods: theoretical design, empirical design, model test design.

5. Commonly used for mechanical components are Materials for mechanical parts include ceramic materials, polymer material and composite materials.

6. The strength of the machined parts is classified into static stress strength as well as variable stress strength.

7. The stress ratio r = -1 is asymmetrical cyclic stress. the ratio r = 0 indicates an elongated cyclic stress.

8. It is believed that the BC stage is known as strain fatigue (low cycle fatigue); CD is the final stage of life fatigue. the line segment following D point represents the infinity life-failure level of the specimen. D is the permanent limit to fatigue.

9. Strategies to improve the strength of parts when fatigued Reduce the impact of stress concentration on cnc milled parts to the greatest extent possible (load reduction groove the open groove) Select materials with strong fatigue strength and also specify the methods for heat treatment and strengthening techniques that increase the strength of fatigued materials.

10. Slide friction: Dry friction boundaries frictions, fluid friction, and mixed friction.

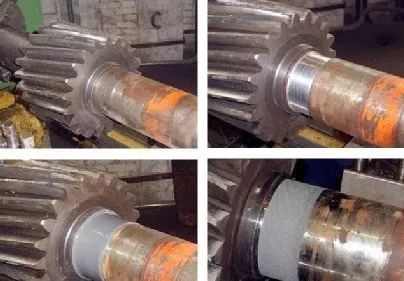

11. The wear process for parts include run-in stage and the stable wear stage and the severe wear stage. Efforts should be made to cut down the time for run-in, extend the period of stable wear and delay the appearance of wear that is very severe.

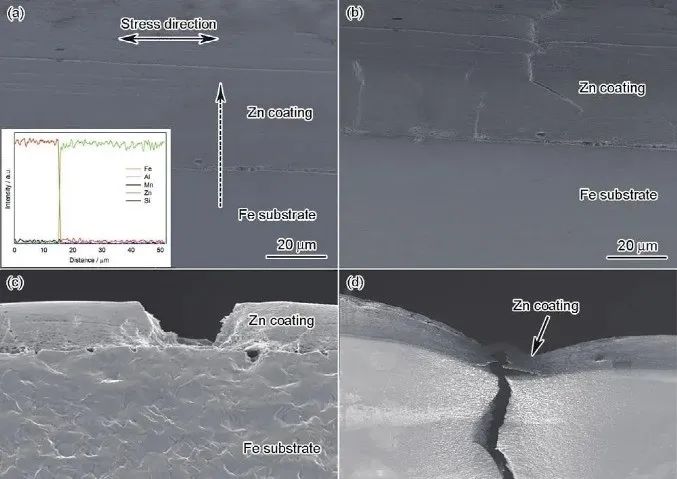

12. The classification of wear is Abrasive wear, adhesive wear and fatigue corrosion wear, erosion wear and fretting wear.

13. Lubricants can be classified into four kinds that are liquid, gas semi-solid, solid and liquid greases are classified as three categories: calcium-based greases nano-based greases lithium-based grease, aluminum based grease, and aluminum-based.

14. The standard connecting thread tooth design is an equilateral triangle that has excellent self-locking properties and the transmission performance of the rectangular transmission thread is superior to the other threads. trapezoidal threads are the most widely employed transmission thread.

15. The majority of connecting threads have self-locking capabilities, therefore single thread threads are commonly utilized. Transmission threads need high efficiency for transmission and therefore triple-thread, or double-thread threads are most commonly used.

16. Bolt connection of the normal kind (through hole or hinged holes that are open on the parts that are connected) connections, stud connections screw connection, set screw connection.

17. The reason for threaded connection pre-tightening is to improve the strength and durability of the connection. It also helps to stop gaps and sliding between the components after loading. The primary issue of threaded connections loosening is to prevent the rotational movement in the screws while loaded. (Friction to prevent loosening, mechanical resistance to stop loosening, dissolving the screw-pair motion relationship)

18. Methods to increase the strength of threaded connections Reduce the amplitude of the stress which affects the strength of fatigue in the bolt (reduce the stiffness of the bolt as well as increase stiffness for connected components) and improve the uneven distribution of load over the teeth of threads, decrease the effect from stress concentration and apply a an efficient manufacturing process.

19. Key connection type Key connection type: flat (both sides have working surfaces) semicircular key connector wedge key connection the tangential key connection.

20. Belt transmission can be divided into two types: meshing type and friction type.

21. The initial maximum stress on the belt is in the point where the tight end of the belt begins to move around the small pulley. The tension changes 4 times during the course on the belt.

22. Tensioning of V-belt transmission: regular tensioning device, automatic tensioning device, tensioning device using tensioning pulley.

23. The chain link count in the roller chain typically equal (the amount of teeth in the sprocket is a strange number) and the over-extended chain link is utilized when the number of chain links is an odd number.

24. The reason for tensioning of the chain drive is to ensure that meshing is not faulty and avoid chain vibration if the sag on the loose end that is too big and also to increase the meshing distance between the chain as well as sprocket.

25. The cause of failure for the gear is tooth breakage, wear on the tooth surface (open gear) the pitting of teeth (closed gear) The tooth surface glueing and deformation of the plastic (ridges are visible on the driving wheel lines appear on the steering wheel).

26. Gears that have a harderness of more over 350HBS and 38HRS are known as hard-faced or, if they’re not, soft-faced gears.

27. Enhancing the manufacturing precision and reducing the size of the gear to lower the speed at which it travels can lower the dynamic load. In order to lessen this load dynamically, the device may be repaired on its top. the teeth of the gear are formed into a drum to enhance the quality of the gear teeth. to load distribution.

28. The greater the lead angle of the diameter coefficient is, the greater the efficiency, and the less secure the self-locking ability is.

29. Move the worm gear. After displacement you will notice that the pitch circles of the as well as the pitch circle overlap, however it is apparent that the worm’s pitch line worm has changed, and it is no longer aligned with its pitch circle.

30. The cause of failure in the worm drive is pitting corrosion and tooth root fractures, the tooth’s surface glueing and excess wear. Failure usually is caused by an worm drive.

31. Power loss from closed worm drive meshing wear loss Wear loss of bearings as well as loss of oil splashes as parts enter in the oil tank stir the oil.

32. The worm drive has to calculate the balance of heat according to the requirement of ensuring that calorific values per unit of time is equivalent to the amount of heat dissipated at the same period of time.

Solutions: Add heat sinks to increase the area for heat dissipation. put in fans at close to the shaft in order to increase air flow, and then install heat sinks inside the transmission box. They can be connected to a circulating cooling pipeline.

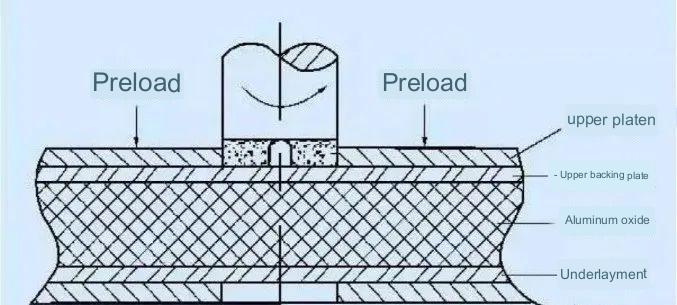

33. The prerequisites for the formation of hydrodynamic lubrication are that the two surfaces which slide must form a wedge-shaped gap. The two surfaces that are separated by the oil film should have a sufficient relative speed of sliding, and its movement should make the lubricating oil flow through the mouth that is large into the smaller mouth. is required for the oil to have a certain viscosity and the supply of oil is required to be adequate.

34. The structure that is the basis of rolling bearings is the outer ring, inner Hydrodynamic body, cage.

35. Three tapered roller bearings five ball bearings with thrust deep groove ball bearings 7 bearings with angular contacts cylindrical roller bearings 01, 02, 01 and 02 and 03 respectively. D=10mm, 12mm 15mm, 17,mm refers to 20mm d=20mm and 12 is equivalent to 60mm.

36. Life of the basic rating: 10 percent of the bearings within an assortment of bearings are suffering from pitting damages, whereas 90% of bearings are not affected by pitting damage. The amount of hours worked is the lifespan that the bearing.

37. The basic dynamic rating: the amount that the bearing is able to support when the base rating of the machine is precisely 106 revolutions.

38. Method for determining the bearing configuration: two Fulcrums are fixed to one direction each. One point is fixed bidirectionally, while the other fulcrum ends up swimming in both directions, while the other ends swim for to provide support.

39. Bearings are classified according to the amount of load shaft (bending moment and torque) mandrel (bending moment) and Transmission shaft (torque).

Anebon adheres to the fundamental idea of “Quality is the essence of a business and the status could be the essence of it” For a big discount on Custom precision 5 Axis Lathe cnc machined parts, Anebon is confident that we will provide high-quality products and services at an affordable cost and excellent after-sales service to the customers. Additionally, Anebon will be able to build a thriving long-term relationship with you.

Chinese Professional China CNC Part and Metal Machining Parts, Anebon depend on top-quality products, perfect design, exceptional customer service and an affordable cost to earn the trust of a large number of customers from both abroad and in the US. The majority of the of the products are shipped to overseas markets.