- Home

- News

- Enhancing Aesthetics and Performance: Professional Approach to Surface Treatments in CNC Machining

Enhancing Aesthetics and Performance: Professional Approach to Surface Treatments in CNC Machining

What do you know about the surface treatment process of materials in CNC machining?

For CNC machining, surface treatment is the process employed to improve the appearance as well as the function and longevity of machined materials. The most common processes used to treat surfaces used in CNC machining include deburring. This procedure involves the removal of sharp edges, burrs, or any excess material off the surface of an machined component. Deburring enhances the aesthetics and safety of the final product.

Polishing: Polishing can be used for smoothing the surfaces of substance which results in a shiny and reflective appearance. It enhances the appearance of components and decreases friction on parts.

Grinding: It is used to eliminate imperfections on surfaces or attain precise tolerances. This involves using a grinder wheel to remove materials from a piece of work.

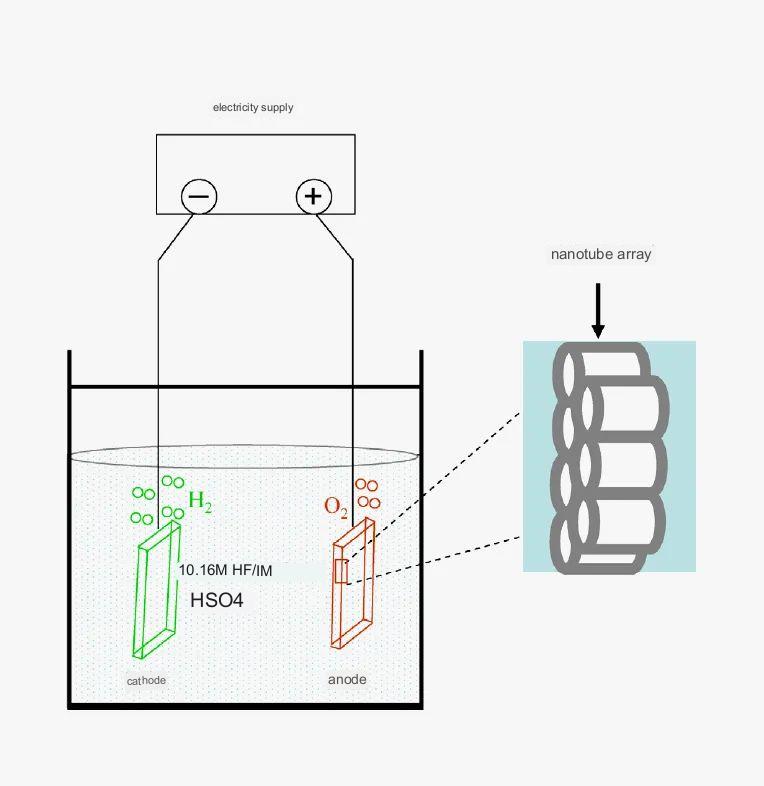

Anodizing: It is an electrochemical process that creates an oxide-like protective layer on the surface of metallic materials like aluminum. It enhances resistance to corrosion as well as aesthetics, hardness and.

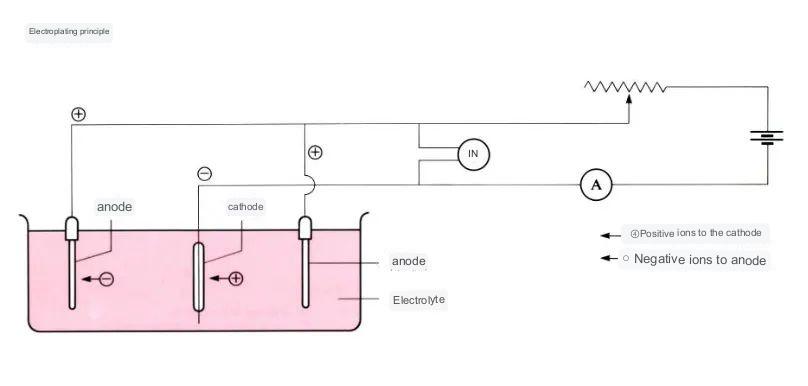

Electroplating involves laying the thin layer of metallic over the top of the material. It improves resistance to corrosion as well as conductivity and looks.

Coating: Surface coating is the process of applying an anti-corrosion layer or paint on the surface of the material. It may provide resistance to corrosion as well as wear resistance. It can also improve the aesthetics.

Heat Treatment: This involves exposing a material to extreme temperature and controlled cool in order to modify their mechanical property. This process improves the material’s durability, hardness and resists wear and deformation.

These treatments for surfaces can greatly enhance the overall quality, performance and longevity of CNC machined components. The type of treatment you choose to use is contingent on the material, its intended application, and the desired results.

Surface treatment is a process to create a over the base material that has chemical, physical, and mechanical characteristics that differ from those of the base material.

The objective of surface treatment is to satisfy the resistance to wear, corrosion and other needs that the merchandise. The most frequently used techniques for treating surfaces include the mechanical grind, chemical treatments surface heat treatment and spraying on the surface. Surface treatment is the process of cleaning the surface, sweep it, deburr it and degrease on the exterior of the piece. Today, we will discuss the procedure of surface treatment.

What benefits can surface treatment bring to machining parts?

Surface area therapy procedures can bring a number of advantages to machined parts, consisting of: Improved Aesthetics: Surface therapies such as sprucing up, anodizing, plating and also finish can boost the visual charm of machined components. It can supply a smooth, shiny or customized finish, improving the total look of the item.

Enhanced rust resistance: Many surface area therapies, such as anodizing, plating, and finishing, create a protective layer on the surface of the material. This layer acts as an obstacle, protecting against the part from coming into contact with the corrosive setting, therefore enhancing its corrosion resistance.

Boosted wear resistance: Surface therapies such as warmth treatment or finishings can dramatically increase the wear resistance of machined parts. These procedures can improve the firmness, toughness and also sturdiness of materials, making them a lot more immune to rubbing, abrasion as well as wear. Boost lubrication and also decrease rubbing: Some surface area treatments, such as polishing or layer with low-friction materials, can minimize friction between moving components. This causes smoother procedure, lowers wear, and also enhances the total performance of machined parts.

Much better chemical resistance: Through surface treatment, the chemical resistance of machined components can be boosted. This is particularly beneficial when components come into contact with hostile chemicals or compounds that can break down the product. Tighter Tolerances as well as Higher Precision: Surface treatments such as grinding or polishing aid attain tighter dimensional resistances and also make sure greater accuracy in machined parts. This is important for applications requiring high precision and also tight tolerances.

Enhanced Adhesion and also Bonding: Surface preparation can create an appropriate surface area for adhesives, paints or other bonding approaches. This allows for a more powerful and also much more reputable bond in between different elements, improving product integrity. Overall, surface treatment processes play a crucial role in optimizing the feature, longevity and also look of machined components, making them more suitable for their desired application and improving their total high quality.

The commonly used surface treatment processes are:

Vacuum electroplating, electroplating process, anodizing, electrolytic polishing, pad printing process, galvanizing process, powder coating, water transfer printing, screen printing, electrophoresis, etc.

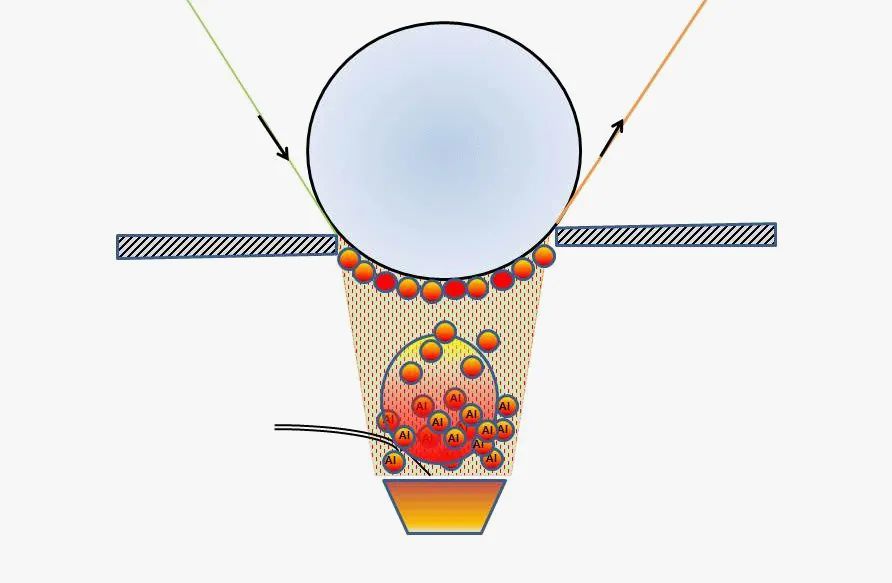

01. Vacuum plating

—— Vacuum Metalizing ——

Vacuum plating can be described as a physical deposition process. In essence, the argon gas is injected into the state of vacuum, the gas atoms hit the material of choice, and the material that is targeted is split into molecules, which are then absorbed by conductive substances to form an uniform and smooth imitation metal layer.

Applicable materials:

1. A variety of materials can be coated, including metals hard and soft plastics, ceramics, composite materials and glass. The most commonly used method of electroplating is aluminum, which is followed by copper and silver.

2. Natural materials aren’t appropriate for vapour plating due to the fact that the moisture in natural materials can alter the vacuum environment.

Cost of the process is the cost of vapour plating the item has to be sprayed unloaded, loaded and then returned to spray, which means the expense of labor is expensive, however it is contingent on the size and complexity of workpiece.

Environmental impact: Vacuum electroplating causes minimal environmental impacts, which is similar to the effect of the process on the surrounding environment.

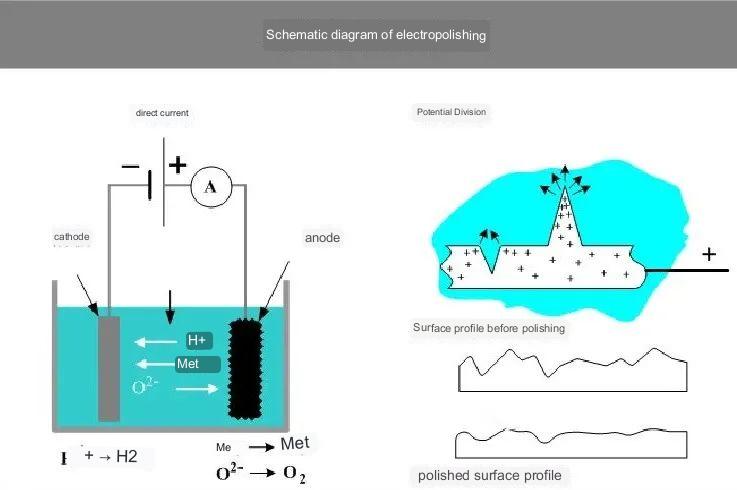

02. Electropolishing

—— Electropolishing ——

Electropolishing refers to an electrochemical procedure whereby the atoms in the cnc turning parts that are immersed in an electrolyte are transformed into ions and then removed from the surface through the flow of an electric charge, which results in getting rid of fine burrs and enhancing the brightness of the surface.

Applicable materials:

1. The majority of metals are electrolytically polished including the polishing of the surface that stainless steel undergoes is the most frequently utilized (especially with austenitic stainless grade).

2. Different materials are not able to be electropolished simultaneously or even within the same solvent for electrolysis.

Cost of the process: The entire electrolytic polishing process is almost entirely automated, meaning the cost of labor is extremely low. Impact on the environment: Electrolytic polishing employs low-impact chemicals. The entire process requires only just a tiny amount of water, and is very easy to use. Furthermore, it may enhance the properties of stainless steel as well as delay the corrosion of stainless steel.

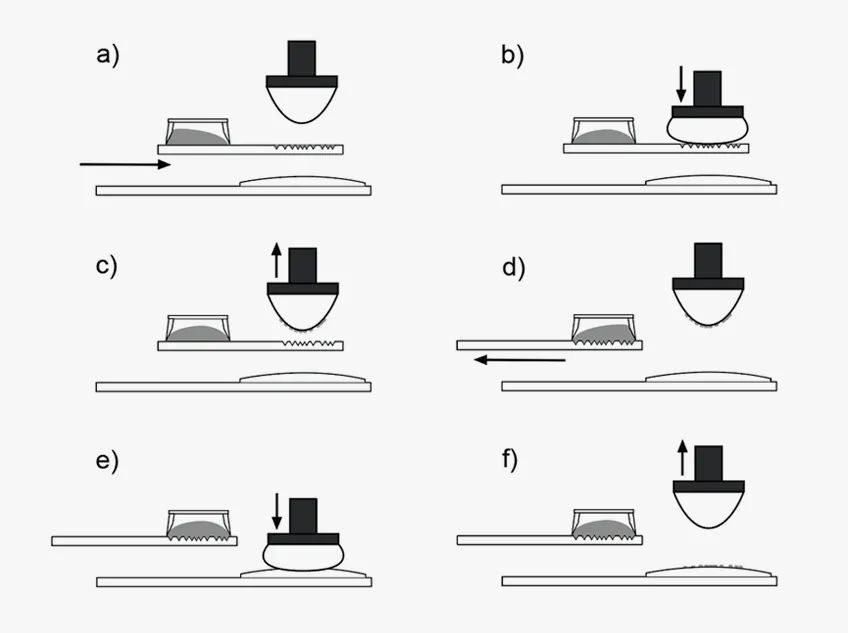

03. Pad printing process

——Pad Printing——

The ability to print images, text and graphics onto the surfaces of irregularly shaped objects is becoming an important aspect of special printing.

Applicable materials:

Pad printing is a viable option on almost any material, other than materials that are more brittle as silicone pads like PTFE.

Process cost Low mold cost and a low labor cost.

Environmental impact: As this process is restricted to inks that are soluble (which are contaminated with harmful chemicals) and has a significant environmental impact.

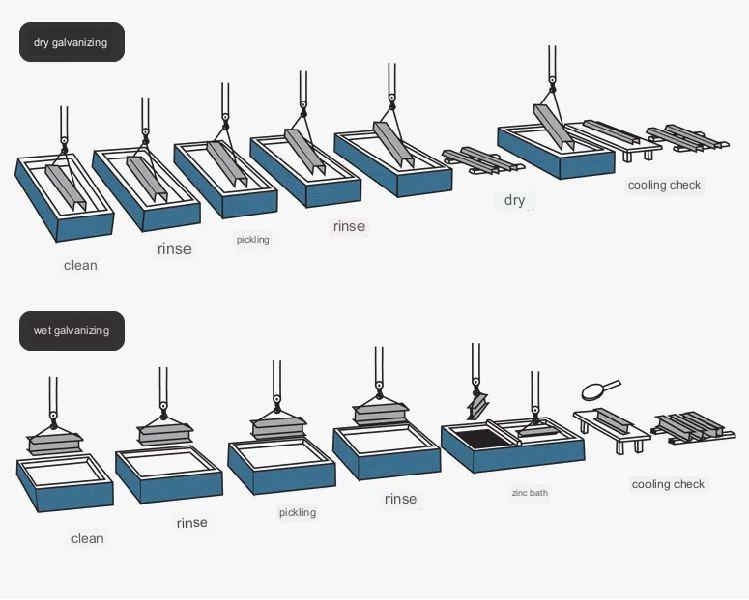

04. Galvanizing process

—— Galvanizing ——

A technology for treating surfaces that coats a layer zinc over the top of alloys made of steel for aesthetics and anti-rust benefits. The zinc coating on the surface acts as an electrochemical protection layer that prevents metal corrosion. The two most commonly used methods are hot-dip galvanizing and Galvanized.

Applicable materials:

Because galvanizing relies on metallurgical bonding this process is suitable for the treatment of surfaces on iron and steel.

Cost of the process: No mold cost, short cycle or medium labor cost, since the quality of the surface on the workpiece is largely determined by the surface treatment performed by hand prior to galvanizing.

Environmental impact: As the process of galvanizing can increase the lifespan of steel parts by between 40 and 100 years and also prevents corrosion and rusting that can occur on it, the process can have an impact on the protection of the surroundings. Furthermore the workpiece that has been galvanized may be taken back to the zinc tank once its time-of-use expires and the continual use of zinc in liquid form doesn’t cause physical or chemical waste.

05. Electroplating process

—— Electroplating ——

The procedure of attaching a thin layer of metallic film to the surface of components through electrolysis, in order to stop metal oxidation, enhance wear resistance the conductivity of light reflection corrosion resistance, and to improve the appearance. The outer layer of a lot of coins can also be electroplated. .

Applicable materials:

1. Many metals are electroplated. However, various metals come with various levels of purity and plating effectiveness. The most popular of these are the following: tin and chromium, silver, nickel, and the rhodium.

2. The most popular material to conduct electroplating is ABS. ABS.

3. Nickel metal should not be used to electroplate products that come in contact with the skin because it is irritant and harmful to skin.

Cost of process: There is no mold costs, however fixtures are required to secure the parts time costs are based on the temperature and type of metal or labor cost (medium-high) is contingent on the specific type of plating components, like jewelry and silverware, which requires a high level of expertise. It is managed by highly skilled employees because of the high demands in terms of appearance and longevity.

The environmental impact of electroplating: A huge amount of toxic chemicals are employed in the electroplating process which is why professional diversion and extraction are essential to minimize environmental impact.

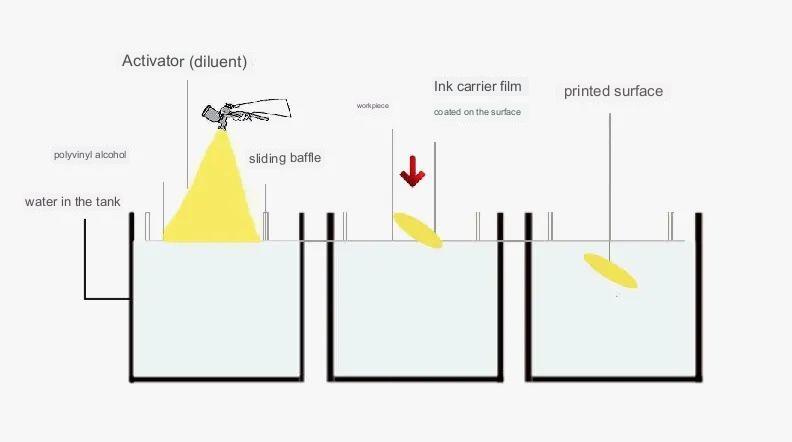

06. Water transfer printing

—— Hydro Transfer Printing ——

It’s a technique to print a color pattern onto the transfer paper the surface of a three-dimensional product using pressure water. As people’s demands for packaging of products and decoration of surfaces the usage of print-on-demand is getting more and more widespread.

Applicable materials:

All types of hard materials are suited for water transfer printing and the materials that are suitable for spraying have to be suitable for printing with water. The most popular are injection-molded parts as well as metal components.

Cost of the process: There’s no mold-related cost, however many products have to be transferred to water at the same time by using fixtures. the total cost is not more than the amount of time per cycle.

Environmental impact: In comparison to spraying on products water transfer printing more completely applies printing paints which reduces the chance of leakage and waste.

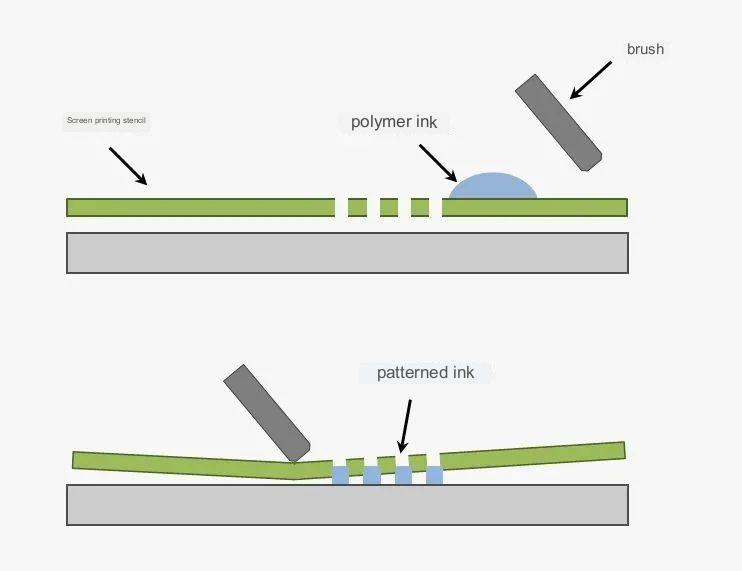

07. Screen printing

—— Screen Printing ——

By extrusion of the scraper, ink is transferred to the surface via it’s mesh and forms the exact same image that was printed in the first. Screen printers are simple user-friendly, and easy to print and make plates, with a low price and an excellent flexibility.

Printing materials that are commonly used include color oil paintings posters, business cards, posters bound covers, commodities signs, as well as dyed and printed textiles.

Applicable materials:

Nearly any material can be screen-printed, including metal, plastic, paper ceramics, glass and more.

Cost of the process The mold’s cost is minimal, but it’s still dependent on the amount of colors used, since each color has to be created on its own. Costs for labor are very extremely high, especially in the case of multi-color printing.

Environmental impact: Screen printing with light-colored inks do not have a negative impact on the environment, however inks that are made up of PVC and formaldehyde are toxic chemical compounds, and require recycling and then disposed of at the appropriate time to stop water pollution.

08. Anodizing

—— Anodic Oxidation ——

The anodic oxidation process for aluminum is primarily is based on the electrochemical concept to create an underlying thin layer composed of Al2O3 (aluminum oxide) film on the aluminum as well as aluminum alloy. The oxide has distinct properties like protection from corrosion, decoration, insulation and resistance to wear.

Applicable materials:

Aluminium, aluminum alloy, and other aluminum products

Process costs: In the process of production the consumption of electricity and water is substantial, particularly during the process of oxidation. The energy consumption by the machinery itself requires to be continually cooled with running water. The power consumption per tonne typically is about 1000 degrees.

Environmental impacts: Anodizing isn’t exceptional in terms of energy efficiency. However, in the process of producing electrolysis of aluminum the anode reaction generates gasses that have harmful adverse effects on the atmosphere’s Ozone layer.

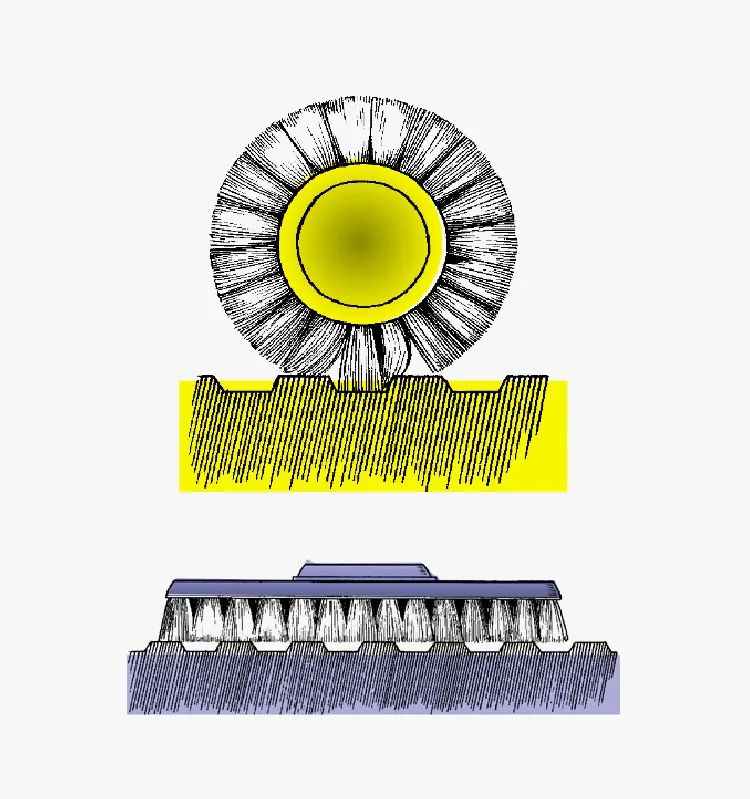

09. Metal wire drawing

—— Metal Wired ——

It is a surface treatment approach that creates lines on the surface of the work surface by grinding the item to attain an attractive impact. According to the various structures after cable illustration, it can be split into: straight cable drawing, disorderly cable drawing, corrugated, as well as swirling.

Relevant materials: Almost all metal materials can make use of metal cord drawing process.

Process expense: The procedure approach is easy, the devices is straightforward, the material consumption is extremely little, the cost is fairly reduced, and also the financial advantage is high.

Environmental influence: pure metal products, no paint or any kind of chemical materials on the surface, 600 degrees high temperature does not melt, does not produce poisonous gases, meets fire security as well as environmental protection requirements.

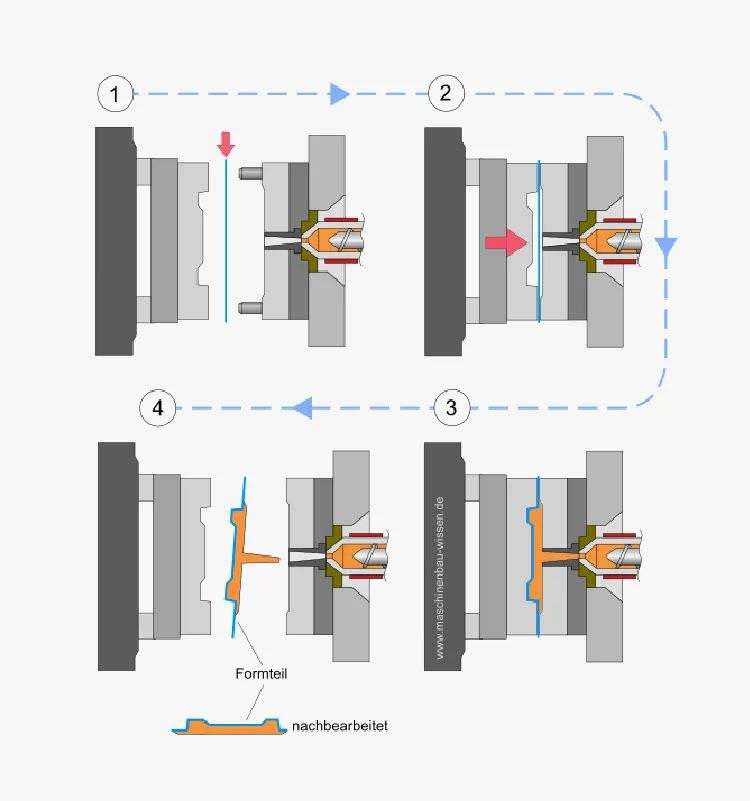

10. In-mold decoration

—— In-Mold Decoration-IMD ——

It is a molding technique that puts the pattern-printed diaphragm right into the steel mold and mildew, infuses the resin for molding right into the metal mold and mildew as well as joins the diaphragm, and makes the pattern-printed diaphragm as well as the resin incorporated as well as solidified right into a finished product.

Appropriate product: plastic surface area

Refine cost: just require to open up a collection of mold and mildews, which can decrease expenses and also man-hours, high-automatic production, simplified manufacturing procedure, one-time injection molding approach, as well as attain molding and decoration at the same time.

Environmental impact: This modern technology is environment-friendly as well as environmentally friendly, preventing the contamination caused by conventional painting as well as electroplating.

Advantages of Anebon are lessen charges, dynamic income team, specialized QC, sturdy factories, premium quality services for cnc machining aluminum parts making service and cnc machining turning parts making service. Anebon set a goal at Ongoing system innovation, management innovation, elite innovation and sector innovation, give full play for the overall advantages, and constantly make improvements to support excellent.

Anebon New Product China Lock-Hole Processing Machine and Aluminum Window Lock Hole Processing Machine, Anebon have complete material production line, assembling line , quality control system, and the most importantly, now Anebon have many patents technology and experienced technical&production team, experienced sales service team. With all people advantages, we’ve been gonna create”the reputable international brand of nylon monofilaments”, and spreading our merchandise to every corner of the world. We have been keep moving and try our best to serve customers of Anebon.