Discover the Top Six Deep Hole Processing Systems Used by Experts

How widely does the well-known deep hole machining system apply to our machining process?

Gun barrels and weapon systems:

Deep bore drilling plays a vital role in the production of gun barrels, ensuring the accuracy and precision of barrel dimensions, rifling, and surface texture.

Aerospace industry:

Deep bore machining is employed in the manufacturing of aircraft landing gear, parts for jet engines, helicopter rotor shafts, and other crucial components that demand exceptional precision and durability.

Oil and gas industry:

Deep hole drilling is utilized in the fabrication of equipment used in oil and gas exploration, including drilling tools, wellheads, and production tubing.

Automotive industry:

The manufacturing of engine components like crankshafts, camshafts, connecting rods, and fuel injection parts necessitates the incorporation of deep holes.

Medical and healthcare:

Deep hole machining is essential in the production of surgical instruments, implants, and medical devices that require precisely crafted internal features and surface finishes.

Mold and die industry:

Deep hole drilling finds application in the manufacturing of injection molds, extrusion dies, and other tooling components that necessitate intricate cooling channels to efficiently dissipate heat.

Die and mold repair:

Deep hole machining systems are also utilized for the repair or modification of existing molds and dies, allowing for the drilling of cooling channels, ejector pin holes, or other necessary features.

Deep hole processing systems: six commonly used models

What is deep-hole processing?

A deep hole is one whose ratio of length to diameter is greater than 10. The depth-to diameter ratio for deep holes in general is usually L/d>=100. These include cylinder holes as well as shaft axial oil, hollow spindle, and hydraulic valves. These holes often require high accuracy and quality of surface, while some materials are difficult to machinate, which can be a problem in production. What are some methods you can think of to process deep holes?

1. Traditional Drilling

The twist drill, invented by Americans, is the origin of deep hole processing. This drill bit has a relatively simple structure, and it is easy to introduce the cutting fluid, allowing for drill bits to be manufactured in different diameters and sizes.

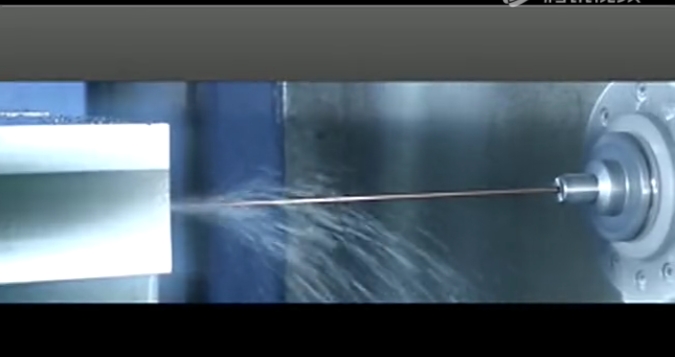

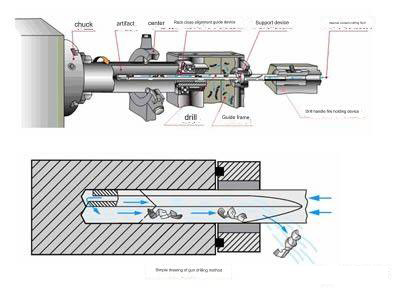

2. Gun drill

The deep hole tube drill was first used to manufacture gun barrels, also known as deep-hole tubes. Gun drill was named so because the barrels were not seamless precision tubes and the precision tube production process could not meet the accuracy requirement. Deep hole processing is now a popular and efficient method of processing due to the development of science and technologies and the efforts of manufacturers of deep hole systems. They are used in many fields, including: automotive industry, aerospace, structural construction, medical equipment, mold/tool/jig, hydraulic and pressure industry.

Gun drilling is a great solution for deep hole processing. Gun drilling is a good way to achieve precise results. Gun drilling can achieve precise processing results. It is able to process a variety of deep holes and also special deep holes like blind holes and cross holes.

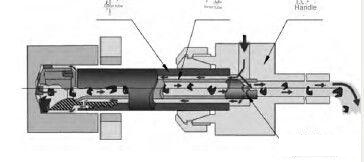

Gun drilling system components

Gun drill bits

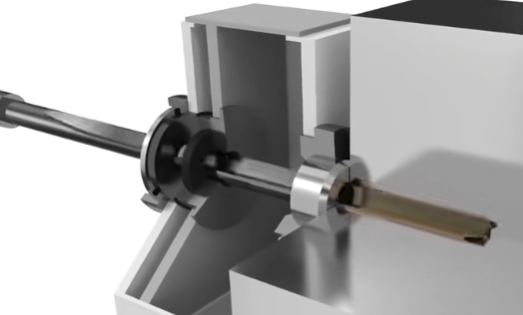

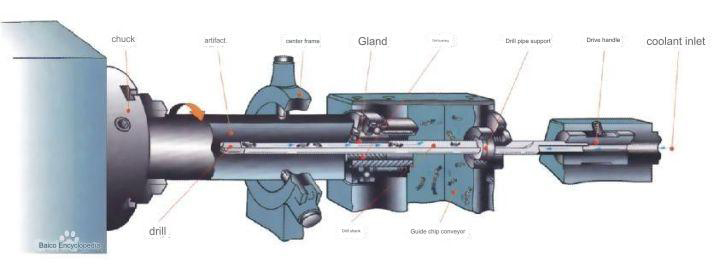

3. BTA system

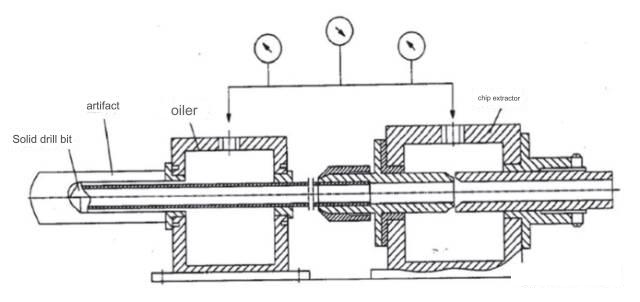

The International Hole Processing Association invented a deep hole drill that removes chips from the inside. The BTA system uses hollow cylinders for the drill rod and bit. This improves rigidity of the tool and allows quick assembly and disassembly. The figure shows its working principle. The oil dispenser is filled with the cutting fluid under pressure.

The cutting fluid then passes through the annular space created by the drill pipe, the hole wall and flows to the cutting area for cooling and lubrication. It also presses the chip into the chips of the drill bit. The drill pipe’s inner cavity is where the chips are discharged. The BTA system can be used for deep holes with a diameter greater than 12mm.

BAT system composition↑

BAT drill bit↑

4. Injection and suction Drilling System

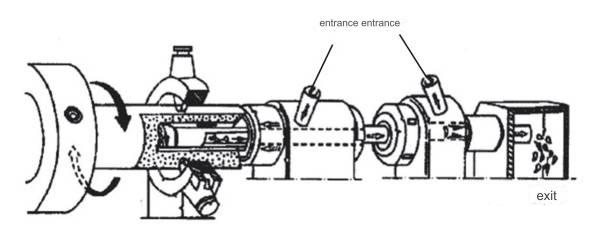

The Jet Suction Drilling System is a deep hole drilling technique that uses a double tube based on fluid mechanics’ jet suction principle. The spray-suction system is based on a two-layer tube tool. After being pressurized, the cutting fluid is injected from the inlet. The 2/3 of cutting fluid that enters the space between the outer and inner drill bars flows into the cnc custom cutting part to cool and lubricate it.

The chips are pushed in to the inner cavity. The remaining 1/3 of cutting fluid is sprayed at high speeds into the inner pipe through the crescent shaped nozzle. This creates a low pressure zone within the inner pipe cavity, sucking the cutting liquid carrying the chips. The chips are discharged quickly from the outlet under dual action spray and suction. Jet suction drilling systems are mainly used for deep hole processing, with a diameter greater than 18mm.

Principle of jet suction drilling system↑

Jet suction drill bit↑

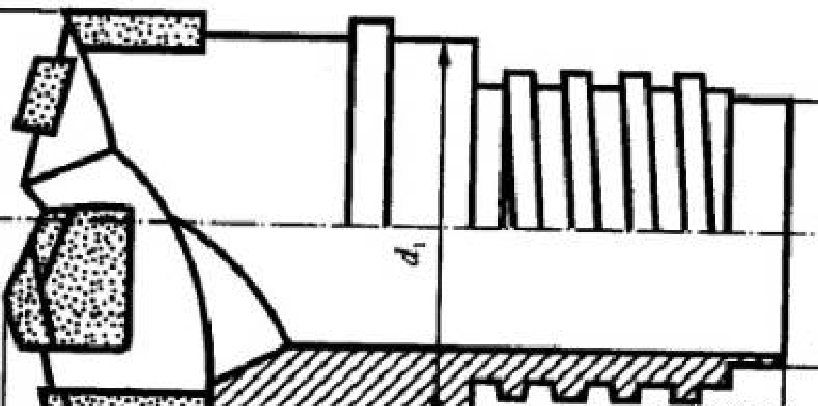

5.DF system

The DF system is a dual-inlet single-tube internal chip removal system developed by Nippon Metallurgical Co., Ltd. The cutting fluid is divided into two front and rear branches, which enter from two inlets respectively. 2/3 of the cutting fluid in the first one flows to the cnc metal cutting part through the annular area formed by the drill pipe and the wall of the processed hole, and pushes the chips into the chip outlet on the drill bit, enters the drill pipe, and flows to the chip extractor; the latter one 1 /3 of the cutting fluid directly enters the chip extractor and is accelerated through the narrow conical gap between the front and rear nozzles, creating a negative pressure suction effect to achieve the purpose of accelerating chip removal.

The structure of the first half of the DF system that plays a “push” role is similar to that of the BTA system, and the structure of the second half that plays a “suction” role is similar to that of a jet-suction drilling system. Since the DF system uses dual oil inlet devices, it only uses one drill pipe. The chip pushing and suctioning method is completed, so the diameter of the drill rod can be made very small and smaller holes can be processed. Currently, the minimum processing diameter of the DF system can reach 6mm.

How the DF system works↑

DF deep hole drill bit↑

6. SIED system

North China University invented the SIED system, a single tube chip ejection system and suction drill system. This technology is based upon three internal chip-removal drilling technologies: BTA (jet-suction drill), DF system, and DF System. The system adds an independently adjustable chip extraction device that is powered by the power supply to control cooling and chip removal fluid flow independently. As shown in the diagram, this is the basic principle. The hydraulic pump outputs cutting fluid, which is then divided into two streams: the first cutting fluid enters the oil delivery device and flows through the annular gap between the drill pipe wall and the hole to reach the cutting part, removing the chips.

The first cutting fluid is pushed into the hole outlet of the drill bit. The second cutting fluid enters through the gap between conical nozzle pairs and flows into the chip extraction device. This creates a high-speed jet and negative pressure. SIED is equipped with two independent pressure regulator valves, one for each liquid flow. These can be adjusted according to the best cooling or chip extraction conditions. SlED is a system which is being gradually promoted. It is a more sophisticated system. The SlED system is currently able to reduce the minimum diameter of the drilling hole to less than 5mm.

How the SIED system works↑

Application of deep hole processing in CNC

Manufacturing of firearms and weapons:

Drilling deep holes is utilized to make guns and weapons systems. It assures exact dimensions, rifling and the surface finish for precise and reliable gun performance.

Aerospace industry:

A deep-hole machining process is used to make parts for landing gears of aircraft as well as turbine engine parts and various other vital aerospace components that require a high quality and precision.

Exploration for oil and gas:

Drilling deep holes is utilized for the production of equipment such as drill bits, pipes, as wellheads, that are essential to the exploration of oil and gas. Deep holes permit extraction of the resources that are trapped in underground reservoirs.

Automotive industry:

Processing of deep holes is essential for the creation of engine components like crankshafts, camshafts as well as connecting rods. These components require precision in their internal features as well as finish for the best performance.

Healthcare and medical:

A deep-hole machining process is used to make surgical instruments, medical implants as well as different medical instruments. These devices require precise internal features and finishes to ensure maximum performance and compatibility.

Mold and die industry:

The deep hole drill plays a crucial role in the creation of molds as well as dies. Molds and dies require cooling channels to ensure efficient heat dissipation when using processes such as injection molding or different manufacturing procedures.

Energy industry:

Deep hole processing is utilized for the manufacture of components that are energy-related, such as turbine blades, heat exchangers and power transmission components. These components typically require precise internal specifications and finishes to ensure efficiency in energy creation.

Defense industry:

Drilling deep holes is used in the manufacture of defense-related cnc milled parts like the missile guide systems and armor plates and aerospace vehicle components. These cnc machined components require high-precision and long-lasting durability to ensure their effectiveness and security.

Anebon is able to supply high-quality merchandise, competitive selling price and finest customer support. Anebon’s destination is “You come here with difficulty and we supply you with a smile to take away” for custom metal stamping service. Now Anebon have been paying consideration on all specifics to insure each product or service contented by our buyers.

We also provide OEM anodized metal and lazer cutting service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, Anebon carefully value every opportunity to provide best products and solutions for our customers.

If you want to know more, please contact the official person in charge of Anebon via info@anebon.com, phone +86-769-89802722