- Home

- News

- Die Casting Heat Treatment Unlocked T6 vs T5 Strategies for Maximum Strength and Ductility

Die Casting Heat Treatment Unlocked T6 vs T5 Strategies for Maximum Strength and Ductility

Content Menu

● Introduction to Heat Treatment in Die Casting

● Understanding T5 Heat Treatment

● The Power of T6 Heat Treatment

● Comparing Mechanical Properties: Real Data and Examples

● Strategies for Choosing T5 or T6

● Challenges and Solutions in Die Casting Heat Treatment

Introduction to Heat Treatment in Die Casting

Aluminum die castings handle a lot in manufacturing, from automotive brackets to electronic enclosures. High-pressure die casting pushes out parts fast with good detail, but the raw material straight from the die often falls short on strength or toughness for demanding jobs. Heat treatment steps in to fix that, changing the internal structure to boost yield strength, tensile strength, and sometimes elongation.

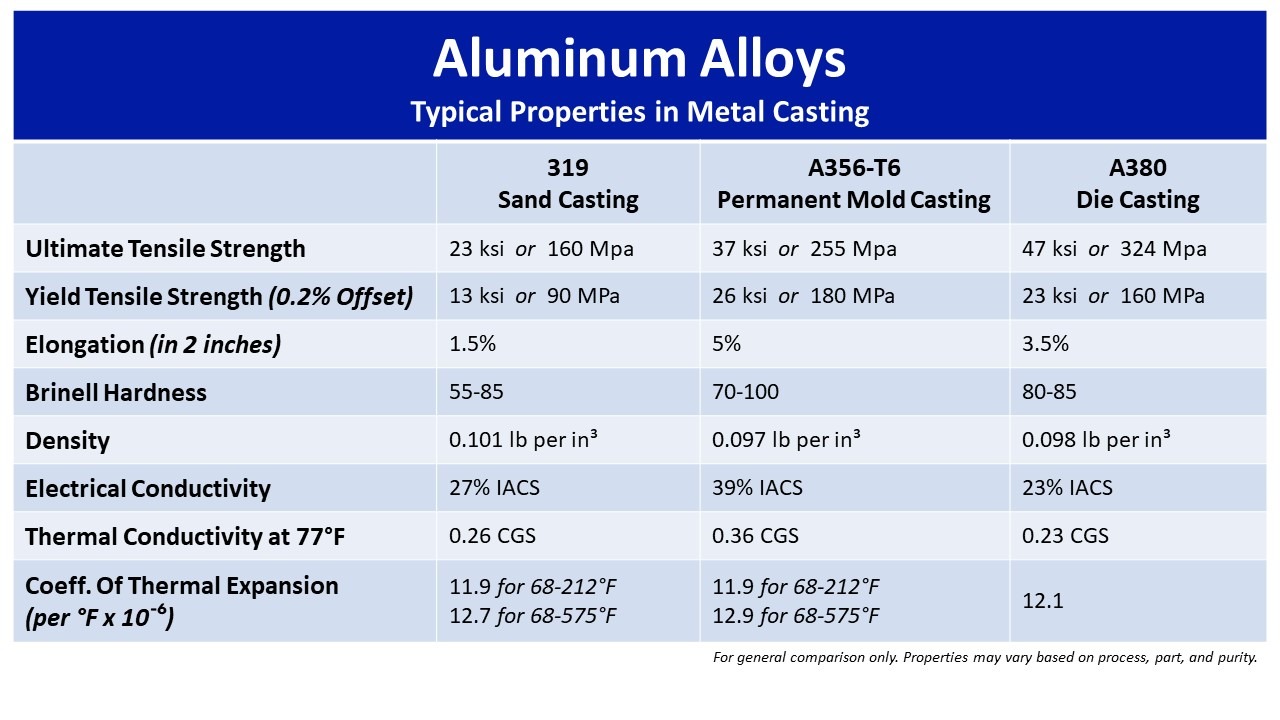

Common alloys here include A380 for general use, with its high silicon for flow, or variants like AlSi9Cu3 with copper for extra hardening. Magnesium additions help with precipitation strengthening. The rapid cooling in the die leaves some elements trapped in solution, setting up for later improvements.

T5 and T6 stand out as the main options. T5 keeps it simple: age the part directly after casting. T6 goes further with solutionizing first, then quench and age. Each has its place depending on porosity levels, part geometry, and target properties.

Take a structural node in an electric vehicle chassis. As-cast, it might hit 150-200 MPa yield, but that’s not enough for crash loads. Proper heat treatment can push that higher while keeping ductility for energy absorption. Work on alloys like AlSi10MnMg shows how short solution times avoid issues in die cast parts. Semi-solid processed materials highlight aging effects clearly.

Real parts show the difference. A pump housing might use T5 for stable dimensions and moderate gains. A suspension arm could need T6 for peak performance, provided the casting process controls gas entrapment.

We’ll cover the steps for each, what happens inside the metal, property comparisons with numbers from studies, and tips for picking the right one.

Understanding T5 Heat Treatment

T5 works straightforward for most die castings. Cool the part from the die, usually in air, then age it artificially at 150-230°C for hours. No high-temperature solution step.

This avoids problems common in die casting. Turbulent flow traps air and lubricant, creating subsurface pores. Heating high for solution expands those, pushing blisters on the surface. T5 stays cooler overall, skipping that risk.

In practice, the fast die cooling already supersaturates some magnesium and silicon. Aging precipitates Mg2Si phases, hardening the aluminum matrix.

For A380 alloy parts, T5 aging lifts yield strength 50-100% over as-cast. Elongation holds at 3-5%, fine for housings or covers. Valve bodies in hydraulic systems often run T5 for consistent properties without distortion.

Electronic heat sinks benefit too. Flatness matters more than ultimate strength sometimes. T5 minimizes warp from quenching.

Another case: secondary alloys with iron. T5 improves hardness without dissolving intermetallics much, keeping costs down.

Limits exist. Eutectic silicon stays acicular, sharp edges that start cracks easier. Partial supersaturation means less precipitate potential than full solution.

The Power of T6 Heat Treatment

T6 aims higher: solution at 480-540°C to dissolve solutes, fast quench to trap them, then age at lower temperatures for precipitates.

Traditional T6 struggled with die castings because of blistering. Now, vacuum systems or short “flash” solutions make it possible for select alloys.

In Al-Si-Mg types, solution rounds eutectic silicon particles. Sharp plates become spheres, cutting stress risers. That alone raises ductility.

Full dissolution allows denser precipitates during aging, often β” phases. Yield can reach 250-300 MPa in optimized parts.

Structural automotive parts like control arms gain from this. Thinner sections possible, lighter overall vehicle.

Secondary AlSi9Cu3(Fe) via semi-solid routes: T6 fragments iron phases, boosts toughness. Elongation jumps from low as-cast to useful levels.

High-copper die castings precipitate additional phases, nearing wrought strengths.

Fatigue improves too. Better distribution handles cycles in mounts or brackets.

Downsides: quench distortion in thin walls, blister risk if pores present. Shorten solution or use air quench to manage.

Microstructural Changes in T5 vs T6

Strengthening relies on precipitates blocking slip.

T5 uses existing supersaturation from rapid solidification. Precipitates form, but silicon morphology unchanged—still fibrous.

T6 homogenizes first, spheroidizes silicon, maximizes solutes for finer, denser precipitates post-quench.

Studies on die-cast relevant alloys show T6 with more uniform structures, less variation across sections.

Comparing Mechanical Properties: Real Data and Examples

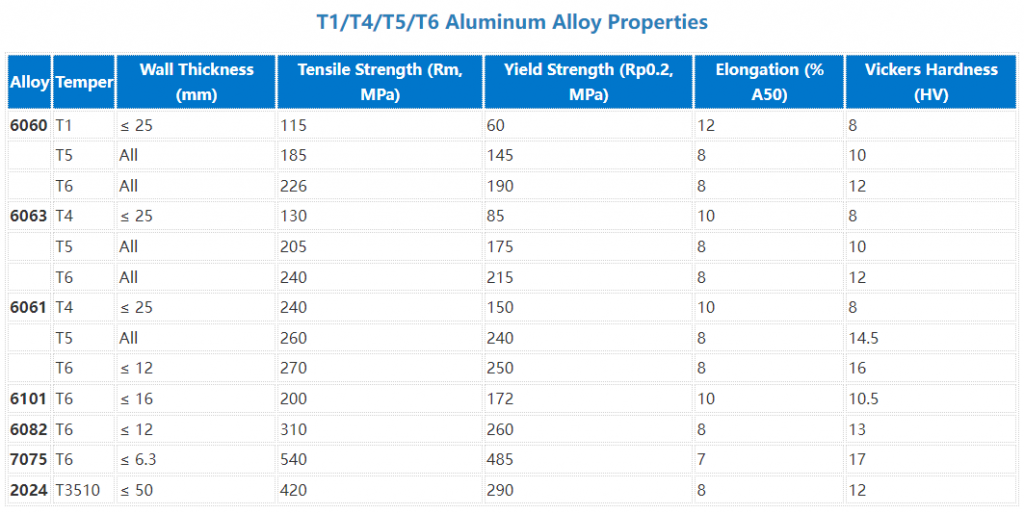

Data from AA365-like alloys in high-pressure conditions:

As-cast: yield around 140-160 MPa, UTS 240-260 MPa, elongation 2-4%.

T5: yield 200-240 MPa, UTS 280-320 MPa, elongation 3-5%.

T6 (modified): yield 260-300 MPa, UTS 330-360 MPa, elongation 5-8%.

Cooling rate variations impact more in T6, but overall superior.

Semi-solid AlSi9Cu3(Fe): T6 hardness up significantly, tensile better than T5.

Examples:

- Battery trays in EVs: T6 for impact ductility.

- Gearbox housings: T5 for stability.

- Wheels: adapted T6 for strength.

Strategies for Choosing T5 or T6

Select T5 when porosity high, tolerances tight, moderate gains enough, cost key.

T6 for max properties, low-porosity castings (vacuum), distortion manageable.

Combine: T5 standard, T6 on critical zones.

Test prototypes always—check blisters, measure sections.

Challenges and Solutions in Die Casting Heat Treatment

Blistering: use vacuum casting, short solution.

Distortion: fixtures, polymer or air quench.

Variation: uniform gating.

T5 lower cost, T6 allows lighter designs.

Detailed Conclusion

Heat treatment opens up die casting potential for tougher applications. T5 delivers reliable boosts with low risk, suiting volume parts needing stability.

T6 pushes limits when controlled, offering strength and ductility gains that enable new designs in lightweight structures.

Match process to alloy and needs. Advances in vacuum and short cycles expand T6 use. Test thoroughly, and heat treatment elevates standard castings to high-performance components in transport and beyond.