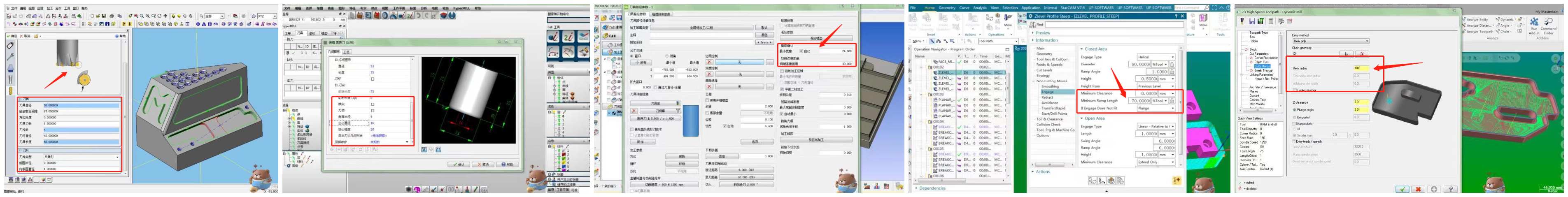

CNC spiral cutting parameter setting

The purpose of all CAM software parameters is the same, which is to prevent “top knife” during CNC machining custom metal service.

Because for the tool loaded with the disposable toolholder (it can also be simply understood that the tool blade is not centered), the tool center is not capable of cutting. If the parameters are set improperly, the tool center will interfere with the workpiece.

How to accurately set the parameters of the fast CNC Milled anti-top knife is calculated by the following formula in the NX software:

(D- r*2)/d, in the formula, d refers to the diameter of the tool (diameter), and r refers to the radius of the tool bottom.

Take the nose knife of D63R5 as an example:

(63-2*5)/63=0.84, that is, the minimum bevel length of the D63R5 tool in the non-cutting movement parameters of the NX software should be set to 0.84, which is a safe “no top tool”.

NX’s algorithm is the percentage of the tool’s non-centered edge to the tool’s diameter. Take D63R5 as an example.

Part without center edge/tool diameter=0.84, derivation is as follows:

Part without center edge = tool diameter X0.84 =52mm

That is to say, the algorithm of NX when filtering narrow areas is: the diameter of the tool without the center edge + the diameter of the tool itself,

That is 52+63=116mm

In other words, when the d63r5 tool is used for rapid prototyping cnc metal processing, the tool path is not generated for the area less than 116 mm, and it is automatically filtered out.

At this point, why set the diameter of the empty blade in HyperMill and set the blade parameters in detail in Esprit. It seems to be twice the result with half the effort.

In the “area filter of PowerMill” parameter, the system default value is 2, which is 2 times the diameter of the tool diameter; in the “minimum width” parameter in WorkNC, the default is 2 times (tool diameter + allowance), it can be said It is safe and proper.

If we also take the nose knife of d63r5 as an example, (tool diameter X 2) = 2 X63 = 126mm, in other words, in PowerMill and WorkNC, for areas less than 116 mm at least, the tool path is not generated, and the CAM software will automatically filter it out.

Then another brother asked, how to set the “HELIX RADIUS” in the feed parameters of MasterCAM. The easiest way is to set the tool diameter. Then the minimum area of the anti-top knife filter is twice the tool diameter.

In fact, like other things, if one software is fully understood, other CAMs are what you want to learn or not learn. If the software parameters are fully understood, the production of high-precision CNC machining parts will be twice the result with half the effort.

If you’d like to speak to Anebon team for Cnc Milling Parts,Cnc Milling Parts Manufacturers,CNC Machining Rubber Parts, please get in touch at info@anebon.com