An In-Depth Study of Screws: A Comprehensive Knowledge Graph

How much do you know about screw processing?

The screw processing process generally involves a variety of steps, starting with raw materials and ending with the final product. Here is a complete description of the most common screw processing techniques:

Selecting the Material:

The selection process begins with the selection of suitable materials for the production of screws. The most common materials are carbon steel, stainless steel brass, copper, or any other alloys of metal, contingent of the required strength and corrosion resistance and other requirements for the application.

Cold Heading:

In this process, the screw blank is made by cold forging or heading. Cold heading is the process of making a rod or wire into the desired shape for a screw by using a head machine. The head machine exerts high pressure to form your blank to a round shape using an elongated head.

Thread Cutting:

In this conventional method using a lathe for cutting screws, a screw is utilized to cut threads or helical grooves within the blank of the screw. The blank is then held in a chuck, while the cutting tool is moved around the axis to make the holes. This technique is suitable to make screws that have various dimensions and types of thread.

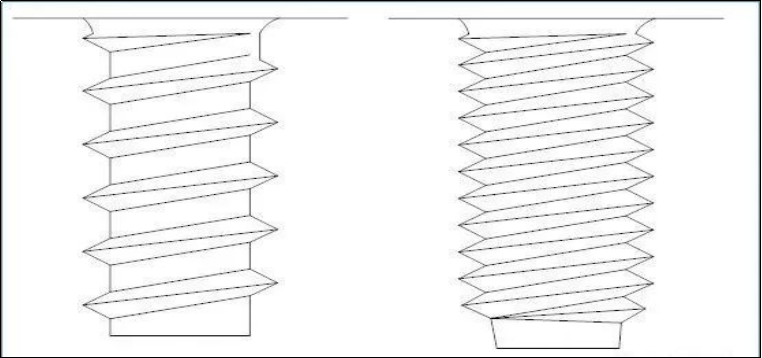

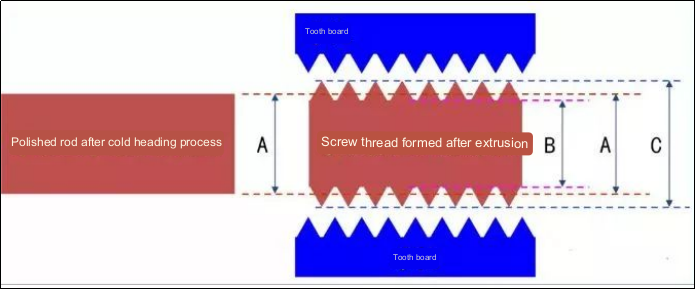

Thread Rolling:

Thread rolling is a different method of making threads for screws. The screw blank is put between two dies that are threaded and then pressure is applied to deform the materials and create threads. Thread rolling creates stronger threads that are more precise and is often used in high-volume production.

Heat Treatment:

Heat treatment techniques like tempering and quenching are frequently used to improve its mechanical characteristics of the screw. These procedures increase the hardness, strength and durability that the screw has, making sure it is able to withstand a variety of stress and loads.

Surface Finishing:

Various surface finishing methods are used to enhance the look and function of the screw. Common surface finishes include zinc plating, nickel plating, galvanizing, black oxide coating, or passivation. These finishes protect against corrosion, increase the durability of the material, and also add aesthetic value.

Inspection and Quality Control:

Quality control checks are performed throughout the process to make sure that the screws are in compliance with the requirements for specifications and standards. Tests, such as thread diameter, pitch length, diameter, and quality of the finish, are used to verify uniformity and precision.

Delivery and Packaging:

After the screws have been inspected for quality after which they are packed and ready to be delivered. Packaging can be made in bulk containers designed for industrial use, or smaller containers to sell retail, depending on the market for which they are intended.

Do you know the terms related to screws?

1. The distinction between screws, nuts or bolts screws, and studs The standard phrase is that there aren’t nuts or screws. Screws are often referred to by their common name for screws, and those that have external threads could be referred to as “screws”. Its shape is typically hexagonal. The inside opening is an inner thread that works with the bolt and tighten associated machining components. Nut is a popular name, and the more common name should be “nut”.

Its head is usually hexagonal, while the shank is equipped with the external thread. The screw is small, and the head is an elongated head or a cross-head, and so on. The shank is threaded externally. Studs ought to be called “double-ended studded”. Both ends are equipped with external threads and the middle part is typically made of a polished rod. The longest part of the rod is connected to the hole in the middle, while the shorter end is linked to the nuts.

2. Common English representation: Screw / Bolt / Fastener (screw/screw) (bolt) (fastener)

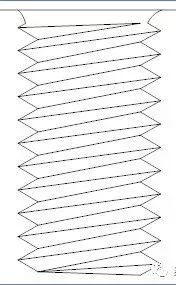

3. Thread definition: it is a shape that has homogeneous helical protrusions that are on the inner or outer surface of an object.

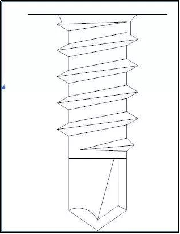

Self-tapping thread: drill holes in the assembly while assembling it, without tapping the thread inside using a bigger torque to assemble.

Self-drilling thread: Applied directly on the assembly the screw is drill and tap simultaneously.

Method for processing screw

1. Turning

Create your material conform to the shape you want by taking the material

Advantages: high precision in machining and no mold limitations

Negatives: high production costs and slow processing speed

2. Forging

Extrude the material with external force, causing it to deform in order to create the desired shape.

Benefits: Fast production speed and low cost, suited for mass production

Insufficient: The form is restricted by molds and mold costs for more complex products is very high.

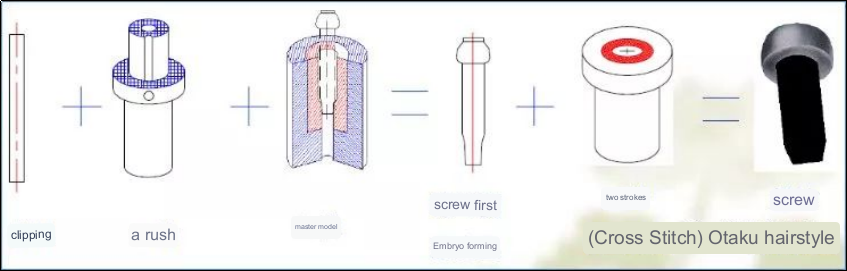

3. Cold heading

It’s the process of extruding and forming the wire of steel by means of external force, under the condition that the wire’s metal doesn’t get hot. The cold-heading process is a type procedure for making forgings.

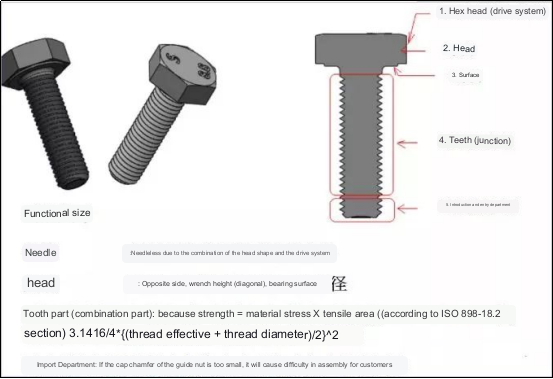

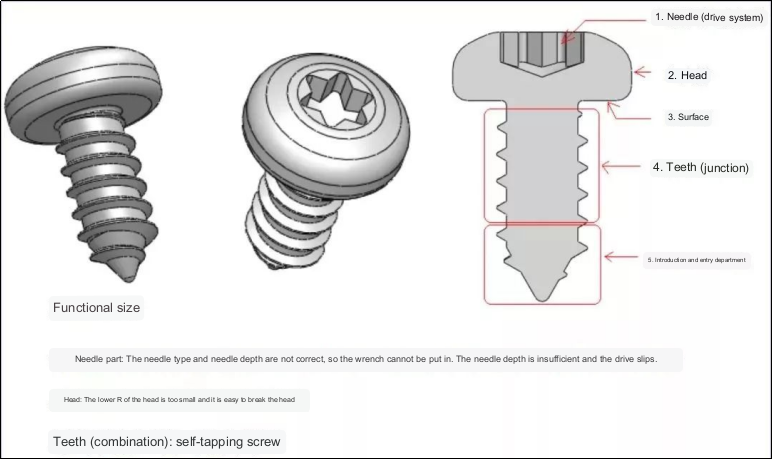

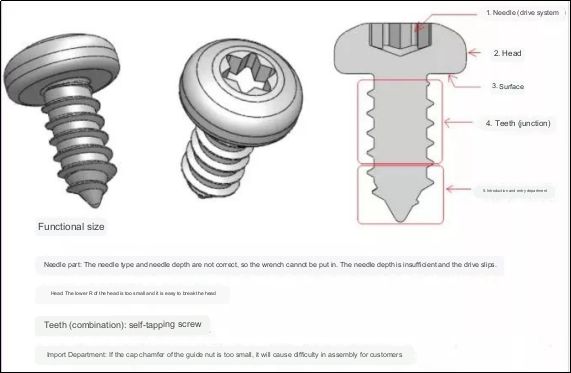

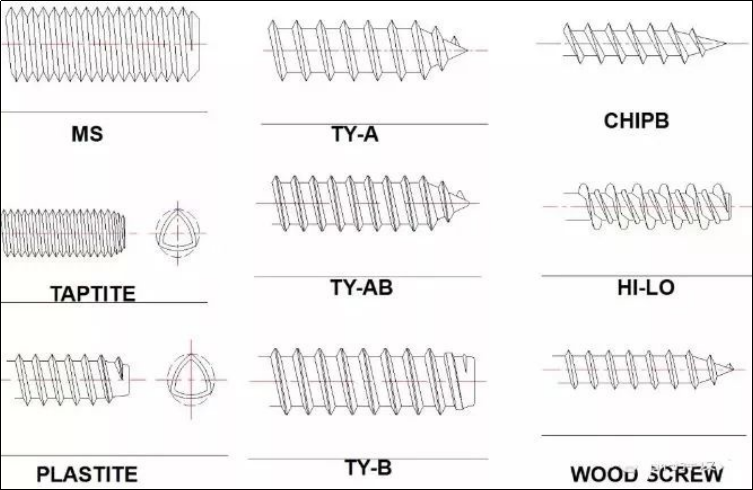

The introduction to the fundamental configuration of screws

To fully comprehend bolts and screws first, you need to be aware of their kinds, features and their functions.

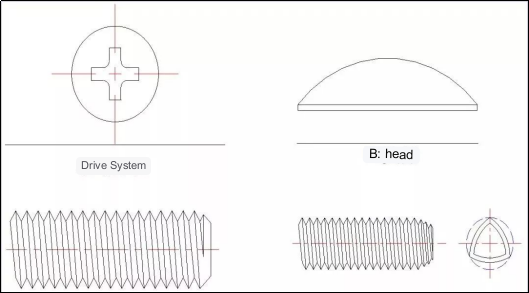

A drive system

B Head

C: Tooth joint

D Department of Import and Attack

Machine screw

Self tapping screw

Triangular tooth screw

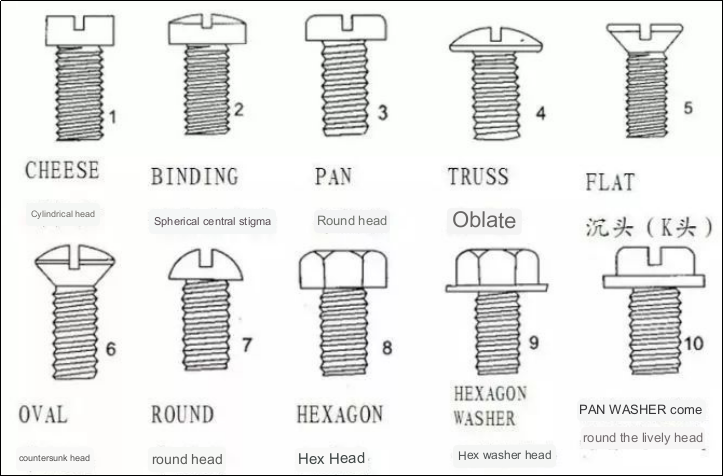

Screw head type

Screw profile

Screw process

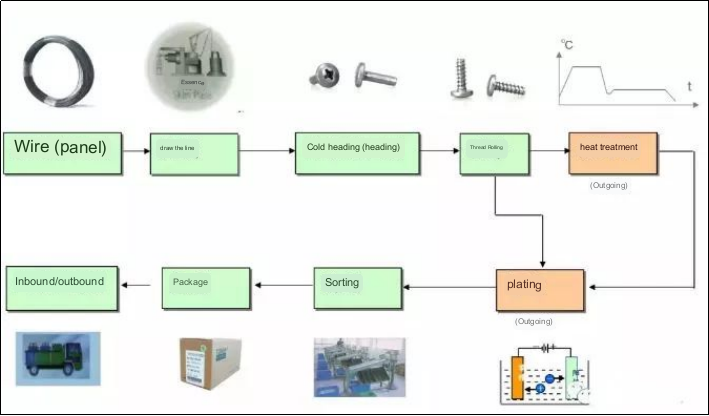

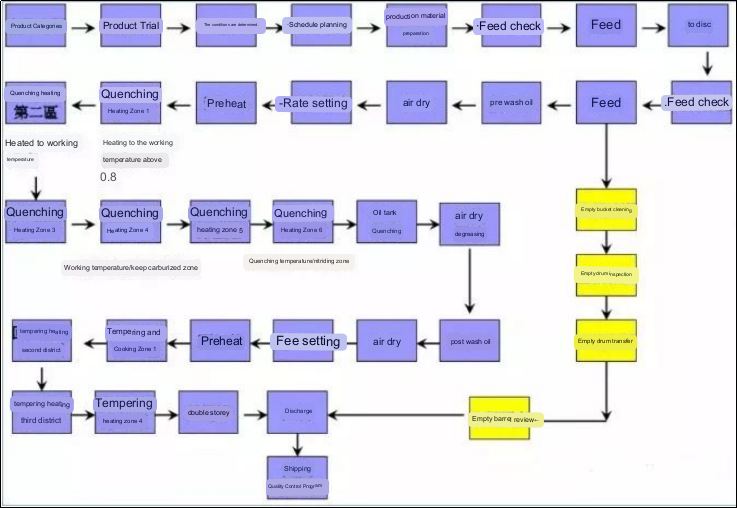

The flow chart’s general format is as the following:

Disk unit process

The original wire rod that was purchased by the supplier of the raw material. A coil is typically comprised of the following cnc machined parts including: A, brand name B C, product name, specification D material E, the furnace’s number, batch number, the quantity or weight. The primary chemical elements of carbon steel discs are: C Mn, P Si Cu and Al The smaller the amount of Cu and Al the more effective.

Drawing process

In order to achieve the wire diameter we need (such as to 3.5mm draw wire).

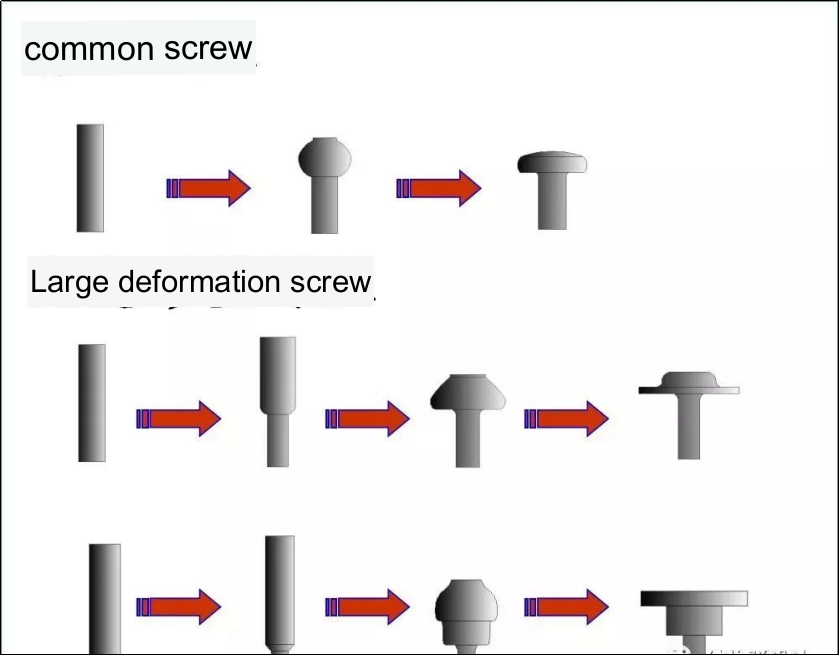

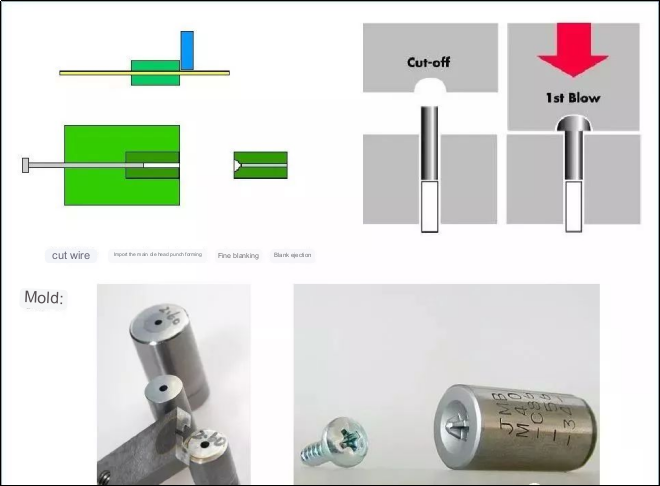

Cold heading (heading) process

Through the interaction between the moulds, it is formed. Firstly, the wire is cut off and upset into a screw blank to form the head, cross groove (or other head type) thread blank diameter and rod length, and rounded corners under the head.

Explanation: It is possible to design it according to customer needs. The most common head types include P heads, B heads, F heads, T heads, etc. Cross grooves, plum blossom grooves, hexagonal grooves, and slotted grooves are all common groove types.

Explanation: It is possible to design it according to customer needs. The most common head types include P heads, B heads, F heads, T heads, etc. Cross grooves, plum blossom grooves, hexagonal grooves, and slotted grooves are all common groove types.

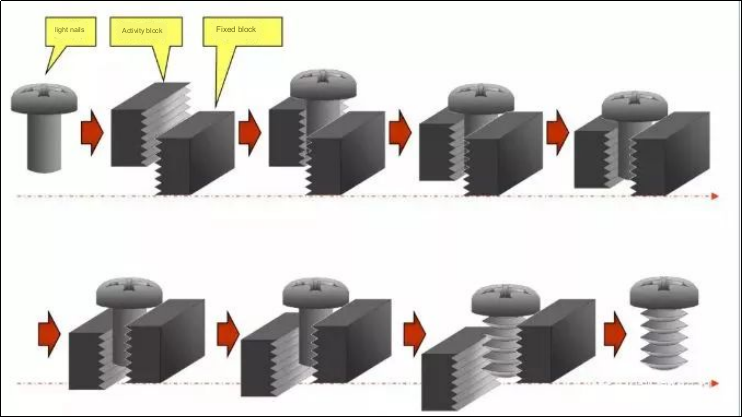

Changes before and after tooth rubbing

Tooth rubbing machine

Rub board (template)

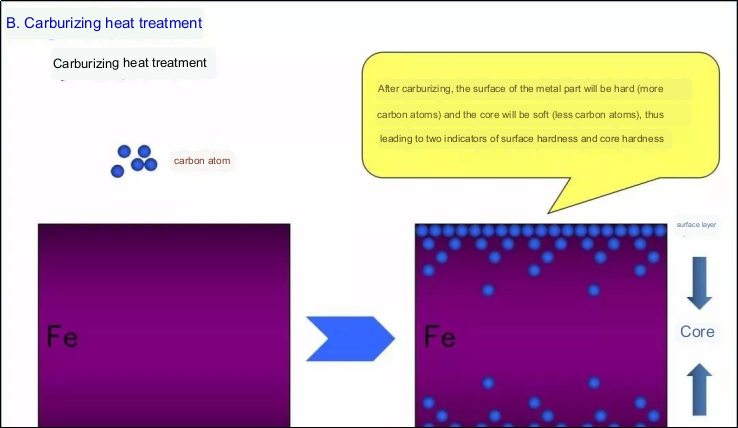

Heat treatment process

1. Purpose: To make the screw get higher hardness and strength after cold heading.

2. Function: Realize the self-tapping locking of metal, improve the mechanical properties of metal parts, such as torsion resistance, tensile resistance and wear resistance. 3. Classification: A. Annealing: (700°C x 4hr): elongated structure – regular polygon.

Cold working structure B. Heat treatment of carburizing (adding carbon to metals to improve their surface hardness) for materials that have low carbon content.

C. Quenching and tempering heat treatment (do not add elements to the metal, change the internal structure of the metal by changing the temperature to obtain better mechanical properties).

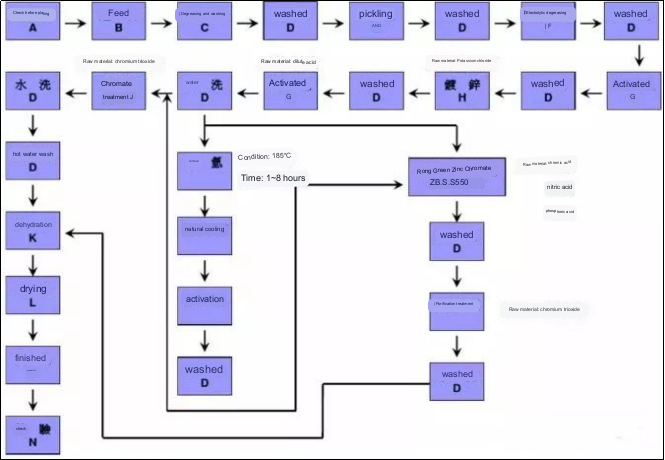

Electroplating Process

After electroplating, the surface of the product can be coated with the desired color and anti-oxidation effect.

Anebon’s goal is to understand excellent disfigurement from the manufacturing and supply the top support to domestic and abroad clients wholeheartedly for 2022 High quality Stainless Steel Aluminum High Precision Custom Made CNC Turning, Milling, Machining Spare Part for Aerospace, In order to expand our international market, Anebon mainly supply our oversea customers Top quality performance mechanical parts, milled parts and cnc turning service.

China wholesale China Machinery Parts and CNC Machining Service, Anebon upholds the spirit of “innovation, harmony, team work and sharing, trails, pragmatic progress”. Give us a chance and we will be going to prove our capability. With your kind help, Anebon believe that we can create a bright future with you together.