A small tap can contain so much information. . .

Tap chipping

Tapping is a relatively tricky machining process because its cutting edge is basically in 100% contact with the workpiece, so various problems that may arise should be considered in advance, such as the performance of the workpiece, the selection of tools and machine tools, and the high cutting speed. , feed, etc.

Choice of taps

Selection of taps and cutting amount

First of all, five questions should be clarified before tapping:

1. What material is the workpiece to be processed?

2. What is the strength of the workpiece material?

3. Are the machined screw holes through holes or blind holes?

4. How deep is the screw hole (or what is the thickness?

5. What are the types and sizes of screw holes to be processed?

The tap should choose an eccentric relief angle from the cutting edge for materials with high machining hardness and strength.Three-axis CNC machining

Selection of Tap Chip Flutes

Appearance drawing of straight groove type, spiral groove type, and apex spiral groove type:

Straight groove, balanced choice.

Spiral Tap

Suitable for blind hole processing, the disadvantage is that the positive edge is too sharp, the durability is not good, and the price is high.

Tip Spiral Groove

It is beneficial for chip removal to be more durable and suitable for through holesthanh straight grooves. The disadvantage is that the invalid wire at the tip is too long.

Simple comparison relationship between straight flute, spiral flute, and apex spiral flute taps:

Spiral fluted tap

Spiral fluted taps are mainly used for threading blind holes. When machining workpiece materials with high hardness and strength, taps with smaller helix angles can improve structural strength.

For machining 400 series stainless steel (15° helix angle)

For machining 300 series stainless steel (helix angle is 41°) Fig. 3 Spiral flute tap

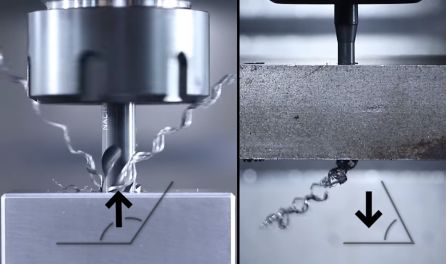

Spiral vs. Apex Spiral

The spiral shape is suitable for blind holes, and the iron filings are discharged to the outside of the hole. The apex is spiral, and the chips are removed downwards. 3d machining

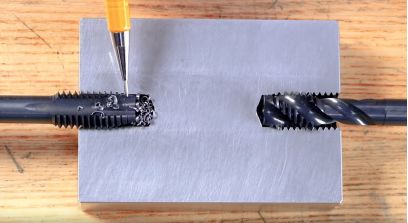

Intuitive comparison of straight and helical shapes

Tapping of unique workpiece materials

The machinability of the workpiece material is the key to the difficulty of tapping. According to the material’s properties, it is essential to change the geometry of the cutting part of the tap, especially its rake angle and the degree of concave in front of the concave amount. Four axis CNC machining

Rake angle and sag

Machining of high-strength workpiece materials

Taps typically have less rake angle and are undercut for high-strength workpiece materials, increasing cutting-edge strength. Long-chipping materials require larger rake angles and undercuts for chip curling and breaking. Machining more complex workpiece materials requires larger relief angles to reduce friction and adequately cool the cutting edge.

Machining materials with different degrees of softness and hardness

The tap should choose an eccentric relief angle from the cutting edge for materials with high machining hardness and strength.

For example, when machining stainless steel materials, a spiral groove with a slight rotation angle is used to cope with the complex and sticky processing characteristics of stainless steel to facilitate long-lasting cutting and chip removal of blind hole tapping.

Common problems in the process of tap-tapping

There are many reasons for tap breakage: machine tools, fixtures, workpieces, processes, chucks, tools, etc., are all possible, and the real reason may never be found on paper. The above problems require operators to make judgments or give feedback to technicians.

Anebon Metal Products Limited can provide CNC Machining、Die Casting、Sheet Metal Fabrication service, please feel free to contact us.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com