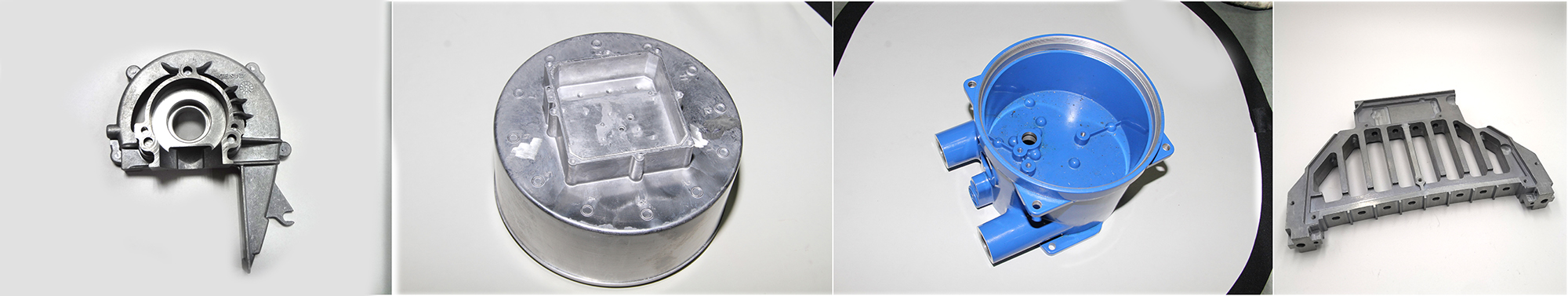

Customized Auto Metal Parts Die Casting

The casting process realizes steel molds that can usually produce thousands of castings in rapid succession. The mold must be made in at least two parts to allow the casting to be removed. The casting cycle starts with the die casting machine clamping the two mold halves tightly together. Molten aluminum is injected into the cavity where it solidifies quickly.

Many parts of the same type that can be cast for mass production. Although high pressure is used in the manufacturing process, high casting quality can still be achieved. The die casting process is particularly suitable for the production of very thin (up to 1 mm) (lightweight) parts.

Frequently produced products: manufactured in the automobile industry, such as wheels, cylinder blocks, cylinder heads, valve bodies and manifolds

| Process: | 1) Die Casting / Profile Extrusion 2) Machining: CNC turning, Milling, Drilling, Grinding, Reaming and Threading 3) Surface Treating 4) Inspection and Packaging |

| Material Available: | 1) Aluminum Alloys Die Casting: ADDC10, ADC12, A360, A380, ZL110, ZL101, etc. 2) Aluminum Alloys Profile Extrusion: 6061, 6063 3) Zine Alloys Die Casting: ZDC1, ZD2, ZAMAK 3, ZAMAK 5, ZA8, ZL4-1, etc. |

| Surface Treatment: | Polishing Shot Blasting Sandblasting Powder Coating Anodizing Chrome Plating Passivation E-coating T-coating etc. |

| Tolerance: | +/-0.05mm |

| Weight Per Unit: | 0.01-50KG |

| Order Lead Time: | 20-45 Days (According the Quantity and Complexity of the Product |

| Cnc Turned Part | Cnc Steel | sheet metal fabrication parts | aluminum casting |

| Motor Hollow Shaft | Aluminum Cnc Turning Parts | sheet metal fabrication process | zinc die casting |

| Turned Parts | Turned Aluminum | sheet metal manufacturing process | casting parts |

Customized Auto Metal Parts Die Casting Related Video: