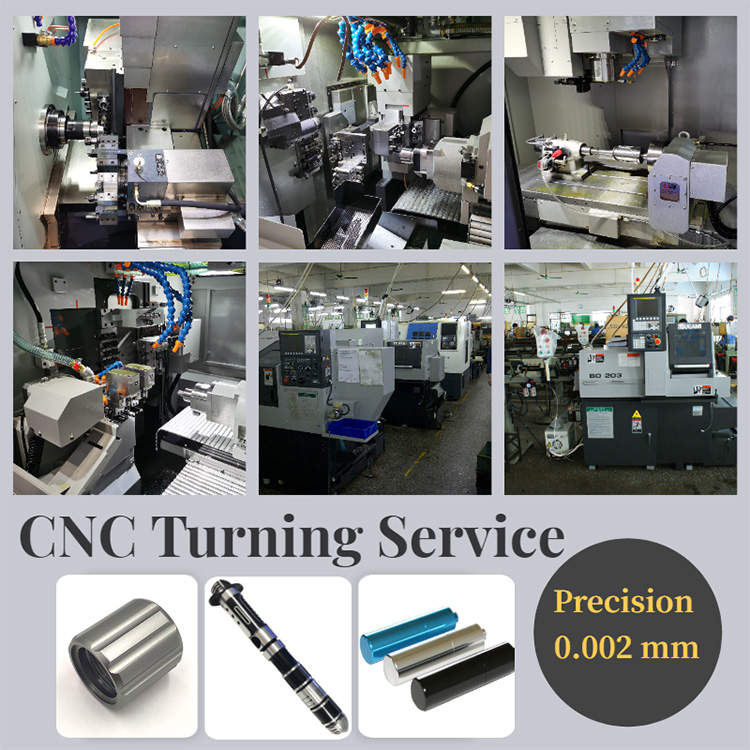

CNC turning process CNC aluminum turning part

Compared with traditional machining, the cutting speed and feed speed are greatly improved, and the cutting mechanism is different. So far, efficient processing is to ensure the quality of processing at the same time using high spindle speed, large feed, deep cutting for efficient processing.

We can manufacture all kinds of fixtures, fixtures, special knives, and our excellent products and services, so that our products serve many companies and industries at home and abroad, and won the praise of our customers.

| Manufacturing Capabilities | Machines:4-axis Machining centers; CNC turning centers; Stamping machines; Tapping machines; Cutting machines; Polishing machines; sandblasting machines; |

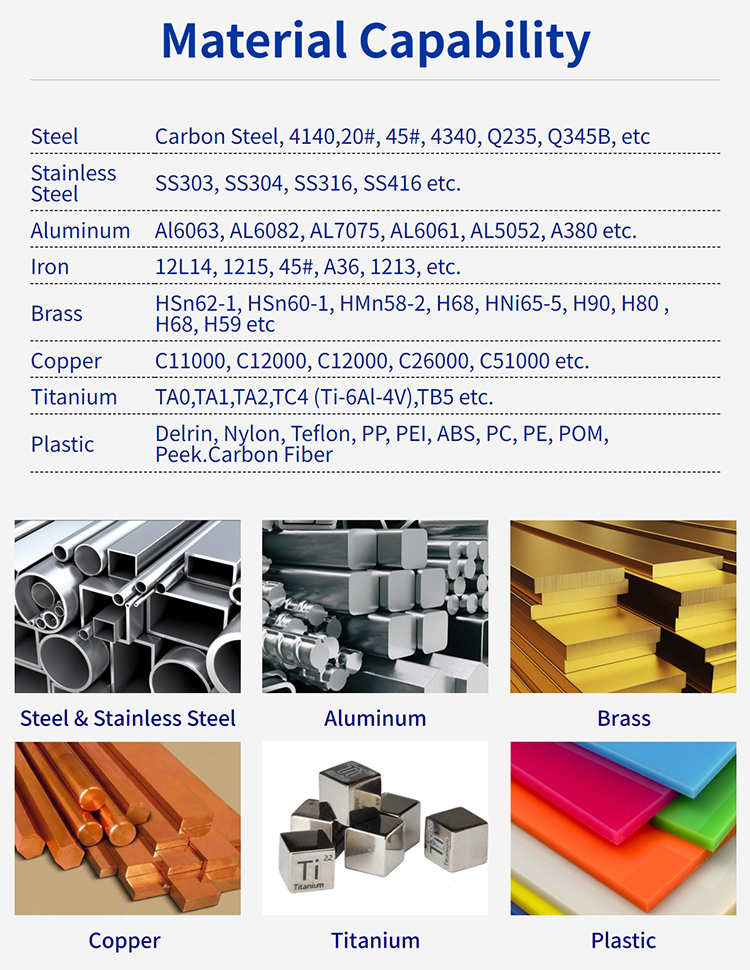

| Materials | Aluminum; Brass; Bronze; Copper; Stainless Steel; Steel / Steel Alloys; |

| Additional Services | CAD/CAM Support; Design Assistance; Just-in-Time Delivery; Prototype Services; Low Volume Production; High Volume Production; Reverse Engineering; Assembly Services; |

| Drawing Software | Solid work, Pro/E, AutoCAD CAM |

| Surface Treatment | As requirement, Zinc plated, Nickel Plated, anodize |

| Standard Available | GB, DIN, ISO, ANSI, ASME, IFI, JIS, BSW, AS, Q, HJ, BS, PEN |

| Delivery Time | 15-25 working days after order confirmation |

| Payment Term | T/T,L/C Western Union, etc |

|

Machining |

Milling |

Turning |

|

Cnc Machining Parts Importers

|

Cnc Milling Parts

|

Cnc Turning Machine Tools |

|

Cnc Machining Parts China

|

Cnc Milling Parts Manufacturers |

Cnc Turning Machine Tool Holders

|

|

Cnc Machining Parts Buyer

|

Cnc Milling Operator |

Cnc Turning Machine Second Hand

|

CNC turning process CNC aluminum turning part Related Video: