Stainless Steel Turned Parts

Product Detail:

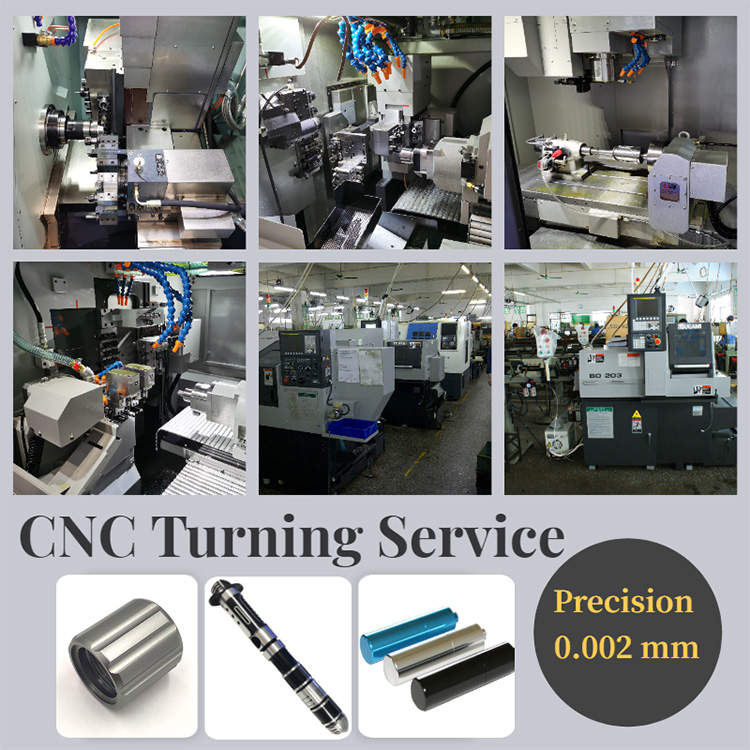

CNC turning parts are lathe machining, and lathe machining is part of machining. The turning machine mainly uses a turning tool to turn the rotating workpiece. On the lathe, drills, reamer, reamer, taps, dies and knurling tools can also be used for machining. Lathes are mainly used for machining shafts, discs, sleeves and other workpieces with a rotating surface. They are the most widely used type of machine tool in machine building and repair plants.

|

Workable size |

Tolerance |

|

|

CNC Turning |

φ0.5 – φ300 * 750 mm |

+/-0.005 mm |

|

CNC Milling |

510 * 1020 * 500 mm(max) |

+/-0.01 mm |

|

Drawing Format |

IGS,STP,X_T ,DXF,DWG , Pro/E, PDF |

|

|

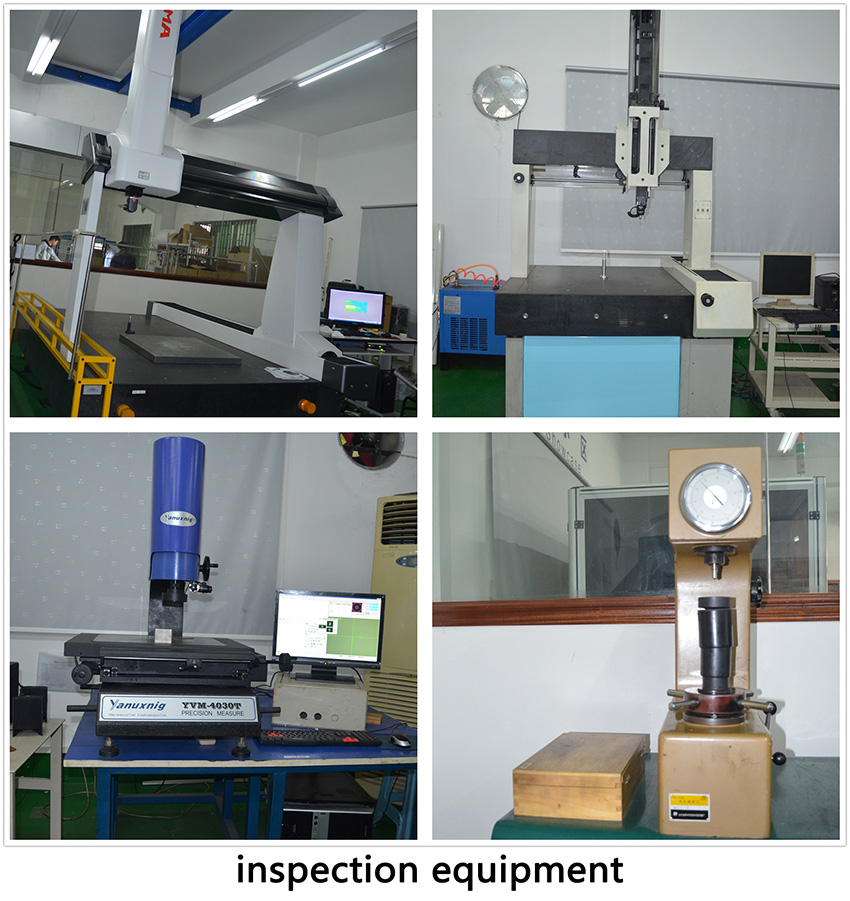

Test Equipment |

Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc. |

|

| Manufacturing Capabilities | Machines: 3-axis Machining centers; CNC turning centers; Stamping machines; Tapping machines; Cutting machines; Polishing machines; sandblasting machines; |

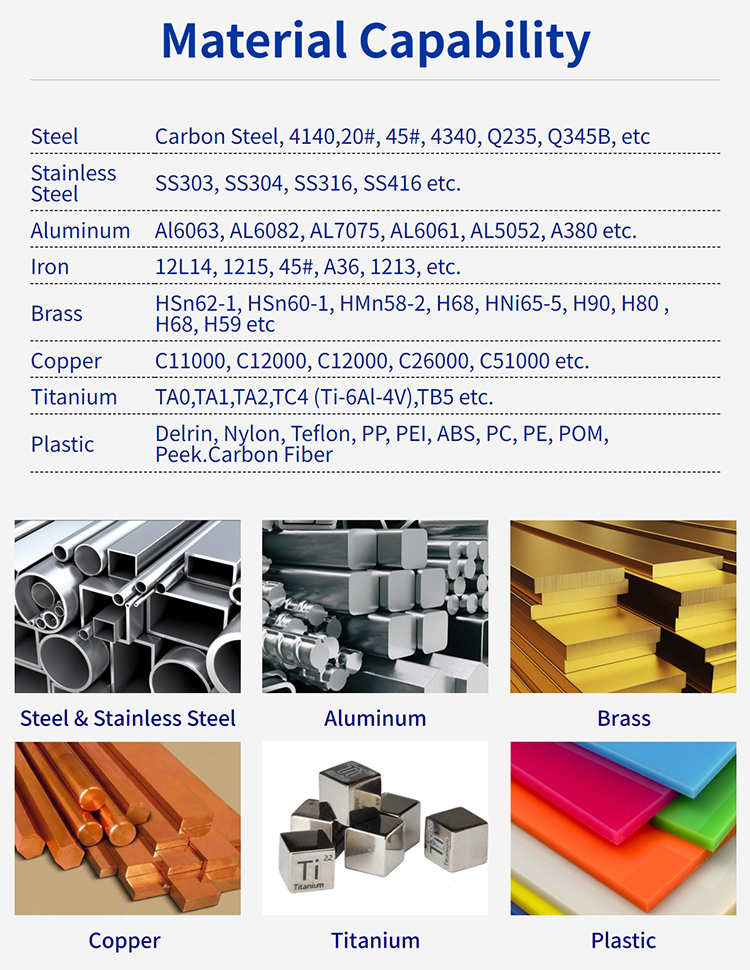

| Materials | Aluminum; Brass; Bronze; Copper; Stainless Steel; Steel / Steel Alloys; |

| Additional Services | CAD/CAM Support; Design Assistance; Just-in-Time Delivery; Prototype Services; Low Volume Production; High Volume Production; Reverse Engineering; Assembly Services; |

| Drawing Software | Solid work, Pro/E, AutoCAD CAM |

| Surface Treatment | As requirement, Zinc plated, Nickel Plated, anodize |

| Standard Available | GB, DIN, ISO, ANSI, ASME, IFI, JIS, BSW, AS, Q, HJ, BS, PEN |

| Delivery Time | 15-25 working days after order confirmation |

| Payment Term | T/T,L/C Western Union, etc |

|

Machining |

Milling |

Turning |

|

Cnc Machining Techniques

|

Cnc Milling Theory

|

Cnc Turning Simulation Software

|

|

Cnc Machining Supplier

|

Cnc Milling Techniques

|

Cnc Turning Setting

|

|

Cnc Machining Stainless Steel

|

Cnc Milling Table |

Cnc Turning Setting Procedure

|

Stainless Steel Turned Parts Related Video: