China Wholesale Stamped Metal Parts Suppliers – Custom 5 Axis CNC Machining Aluminum – Anebon

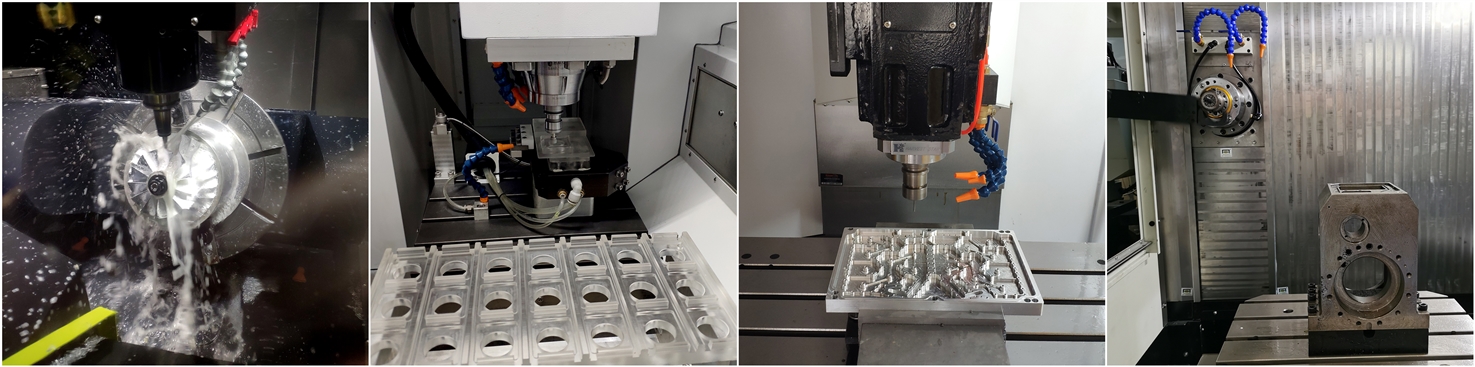

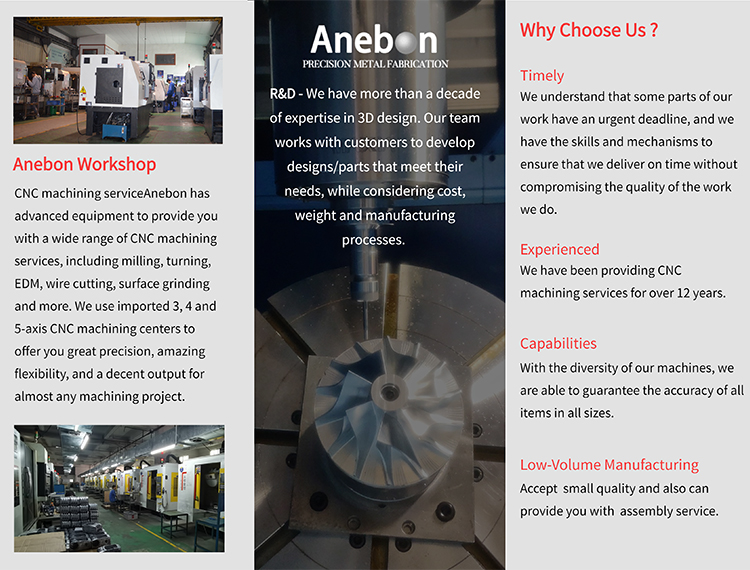

For any company, investing in the latest technology is a requirement to stay ahead and compete effectively. In order to meet this requirement, customers’ products are becoming more and more complex and sophisticated. This means that the demand for 5-axis cnc machining is also increasing. Even if you do not need 5-axis machining, the parts produced on a 3-axis machine tool will be more effective when performing 5-sided machining on a 5-axis machining center.

When performing 5-axis machining at the same time, you can use a shorter tool, which means you can push the tool faster at a higher feed rate. Using 5-axis simultaneous machining for mold processing means you can make larger cuts, and the z depth is not a problem. All of this reduces the total processing time.

Advantages of 5-axis machining:

Reduce setup time

Higher precision

Expand store capacity to cope with future work

Cut faster

Fewer tool interference issues

Excellent roughing strategy

Better surface finish

Longer tool life

Make tools reach difficult places smoothly

| Cnc Machined | 5 Axis Machining | Micro Cnc Milling |

| Online Cnc Machining Services | Cnc Machined Components | Cnc Production |

| Rapid Cnc Machining | Cnc Machined Part | Cnc Process |

China Wholesale Stamped Metal Parts Suppliers – Custom 5 Axis CNC Machining Aluminum – Anebon Related Video: