China Wholesale Sheet Metal Stampings Suppliers – OEM Customized Metal Stamping Part – Anebon

Product Detail

Product Description

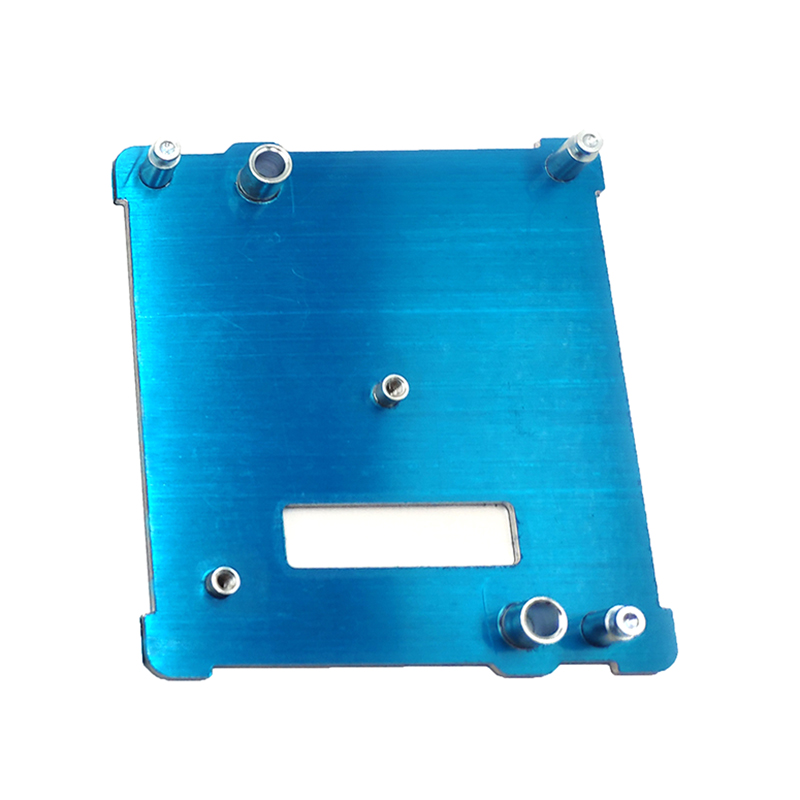

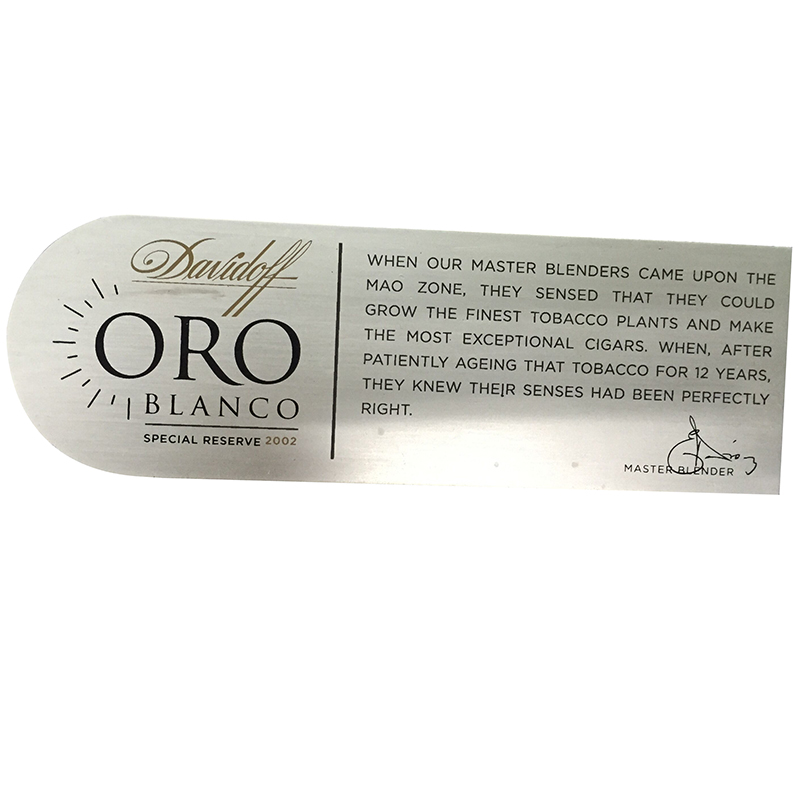

As per the miscellaneous necessities of our regulars, we are betrothed in offering a wide collection of Electrical Stamping and gasket. In association with the quality values defined by the market, these offered products are highly acclaimed. Along with this, these can be altered as per the demands of our regulars.

Features:

- Long lasting

- Seamless finish

- Exceptional functionality

| Product Shape | Various shapes are available |

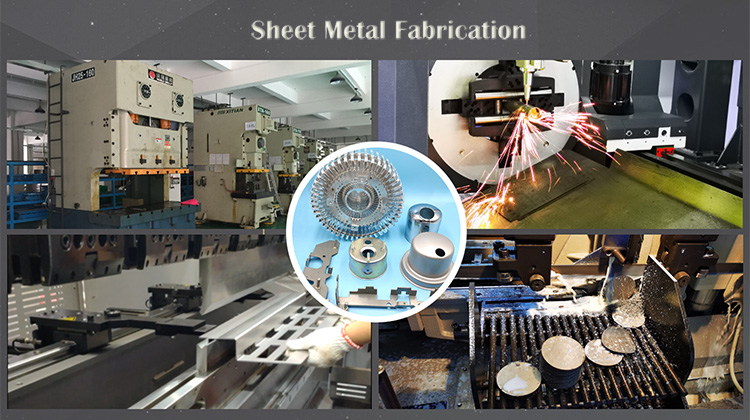

| Processing Type | Stamping & CNC Machining |

| Tolerance | as per customers’ requirement. |

| Material Standard | ISO, DIN, ASTM, UNS, AISI, JIS, BS, NF |

| Materials available | sand casting, investment casting, die casting, permanent mold casting, forging, stamping, welding, and CNC machining |

| Material Thickness | as per customers’ requirement. |

| Surface Treatment/Finish | Anodize, Chromate, Electrolytic Plating, Nickel Plating, Galvanize, Tempered, Paint, Powder Coating, Polish etc., |

| Heat treatment capability | Annealing, Normalizing , Nitriding, Tempering ,Carbonitriding |

| capability | Carburizing and induction hardening etc., |

| Industry Of Use | Used in metallurgy, automobile, aero, chemical, ship hardware, and other industries |

| Quality Assurance | ISO 9001:2015, RoHS |

| Sample Lead-time | About 2 weeks for custom samples |

| Price Terms: | EXW/FOB/CFR/CIF Shanghai or any other airport or seaport, China |

| Modification | Mould modification until the customers satisfy it. |

| Inspection | In-house or third party, all the products are strictly inspected by skilled QC |

| Design: | We use the most advanced mould design software Auto CAD, Pro/E, Solidworks, UG (dwg, dxf, IGS, STP, X-T) |

| Country of Origin | China (mainland) |

| Main Export Markets | Europe, America, Mid East, Asia etc., |

| Business Type | Manufacturer, Exportor |

Product Tags

China Wholesale Sheet Metal Stampings Suppliers – OEM Customized Metal Stamping Part – Anebon Related Video: