China Wholesale Milling Aluminum Plate Suppliers – CNC Rapid Prototyping Metal Parts – Anebon

Hot sale precision customized CNC machining metal parts CNC milling parts

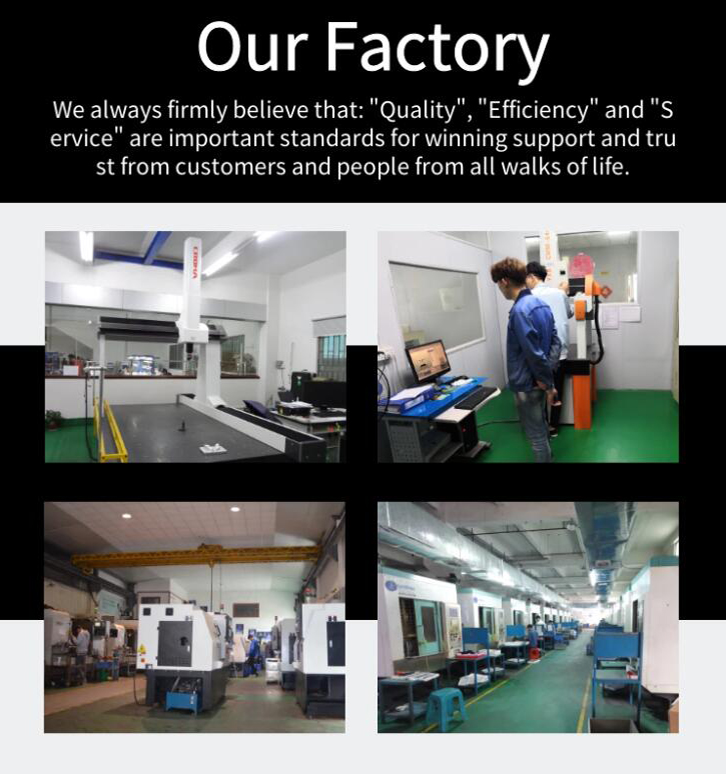

We are committed to strict command of the highest quality and thoughtful procurement support. Our experienced employees and customers can discuss your necessity at any time, and will fully meet the customer’s demand for the factory’s hot sale CNC Rapid Prototyping Metal Parts.

Our factory is for CNC milling parts, precision CNC machining parts, customized CNC machining metal parts. We care about every link of our service, from factory selection, product development and design, price negotiation, inspection, delivery to after-sales market. We have implemented a strict and complete quality control system to ensure that every product can meet the quality requirements of customers. In addition, all our products are strictly inspected before shipment. Your success, our honor: our goal is to help our customers achieve their goals. We are trying to achieve this win-win situation.

| Standard | GB/ISO2768-M, GB/T6892-2006 | |

| Certification | ISO9001,ISO14001 | |

| Production process | Drawing-Openning mould-Raw material -Molding-Deep processing-Surface treatment-Inspection- Packaging | |

| Processing technology | Extrusion/die casting/forging CNC machining such as drilling ,milling ,turning,bending ,cutting ,welding, punching ,etc. |

|

| Deep Process Equipment | CNC Punch | Punching/stamping-High precision Sheet Metal Fabrication |

| CNC Bending | Bending-High precision seamless bending | |

| CNC Milling | High precision mlling, numerical control carving and milling,CNC engraving and milling | |

| CNC Machining Center | Milling, drilling,turning, threading, tapping, boring, facing, spotting, counterboring | |

| Welding | GMAW WeldingMIG Welding | |

| Laser cutting | High precision cutting | |

| Surface treatment | Mirror anodizing | By buffing and anodizing process to form mirror like finish |

| Common anodizing | Anodizing layer=10um ,color can be customised | |

| Hard anodizing | Aanodizing layer≥40um ,color can be customised | |

| Drawing/brushing | By brushing and chemical process to form shining with line | |

| Oil /Baking Paint | Color can be customised | |

| Powder coating | Form a thick layer protect the surface, good corrosion resistance | |

| Polishing | Finish of aluminum itself ,shine metal | |

| Electrophoresis | Based on anodized process, an extra transparent film makes the surface clearer and look bit of shining ,good corrosion resistance | |

| Sand blasting | Making the surface roughness and cleanliness ,improves the fatigue resistance and adhesion strength of the artifacts | |

Our Company Advantage:

| 1. We are factory providing CNC service and machining metal parts |

| 2. Handling components of very tight tolerance and very complex geometry |

| 3. Low MOQ (10pcs is even acceptable in some special conditions) |

| 4. Offering free and quick prototyping ( normally 1 week) |

| 5. Delivery on time |

| 6. Top quality guaranteed by skilled workers, managing system and status of facilities. |

| 7. A series of secondary service available, like casting; forging; welding; heat treatment etc. |

| 8. Offering consultancy service on components machining |

| 9. Customized size and spec /OEM available |

|

Cnc Machinery Parts |

Aluminum Cnc Machining Service |

Metal Cnc Services |

|

Aluminum Machining Parts |

Axis Machining |

China Cnc Service |

|

Aluminum Cnc Parts |

Machining |

Custom Made Aluminum Parts |

China Wholesale Milling Aluminum Plate Suppliers – CNC Rapid Prototyping Metal Parts – Anebon Related Video: