China Wholesale High Pressure Aluminum Die Casting Suppliers – Aluminum Alloy High Pressure Casting – Anebon

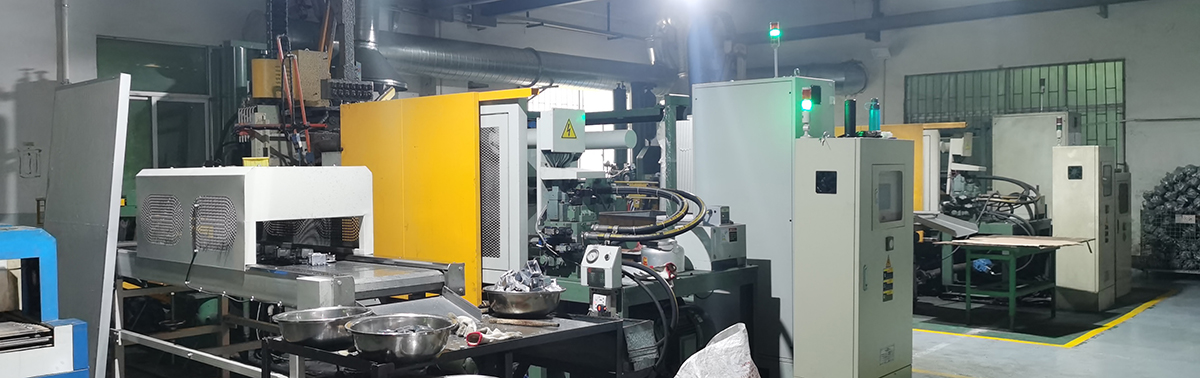

The Anebon factory and employees can perform non-die casting, large-volume CNC machining production and fast turnover. Our testing and quality assurance process ensures that we provide the highest quality die-cast CNC machined products.

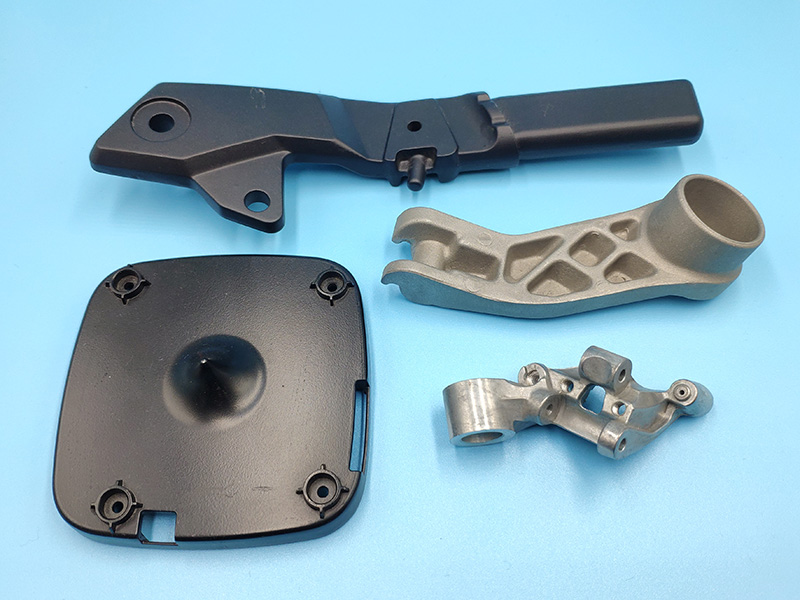

From design concept to production and packaging, Anebon solved the problem. Our customers value our ability to turn complex design specifications into reality.

Our team combines technical expertise with years of process and design experience, and can participate in hundreds of high-mix and small-batch projects every year. This provides our clients with flexibility and the ability to personally follow all of their projects.

There are two main types of die casting machines:

Hot cell machine (used to melt low temperature alloys, such as zinc)

Cold room machine (used to melt high temperature alloys, such as aluminum)

In both machines, after the molten metal is injected into the mold, the metal quickly cools and solidifies into the final part, called a casting. Usually, the casting will undergo one or more finishing processes before final assembly.

| casting parts | Stainless Steel Cnc Machining Services |

| aluminum die casting parts | Cnc Machining Services |

China Wholesale High Pressure Aluminum Die Casting Suppliers – Aluminum Alloy High Pressure Casting – Anebon Related Video: