China Wholesale Cnc Machining Services Near Me Suppliers – CNC Machining Microphone Parts – Anebon

Product Detail

To develop from “Made in China” to “Innovated in China” is the particular historical mission endued by the era to the national enterprises, especially to the leading enterprises of the industry. By the top power of mould technique and engineering manufacturing, Yaxing provides customers with “one-stop” all support services ranging from product development, mould manufacturing, molding, secondary processing to assembly.

|

Electronic parts |

Size | Depends on customers requirement (2D/3D) |

| Color | All | |

| Function | Plastic parts in electronic products,including functionality and aesthetic | |

| Use | Electrical application,automatic,O/A,toys,etc | |

|

Service |

One stop service | Design- Mockup- Manufacturing- Assembly |

| Design | CAD/CAM technical platform and perfect engineering data switching system which enable us to have elastic choices to offer service to our customers. UG 4.0, UG8.0, Solidworks DXF, DWF, PRT, SAT, IGES or STE format for mold design and layout |

|

| Mockup | Rapid laser mockup /CNC mockup process | |

| Manufacturing | Prototype mold,production mold,plastic parts production | |

| QC | Latest precise detecting instruments Well trained and skillful inspectors Timely feedback to manufacturing department High yield rate and timely delivery | |

| Delivery | SAMPLES SHIPPED BY FEDEX,DHL ,UPS Sea or air shipment for Mold/mass production |

Application

- Cost effective for low-volume production(1-100 pcs part)

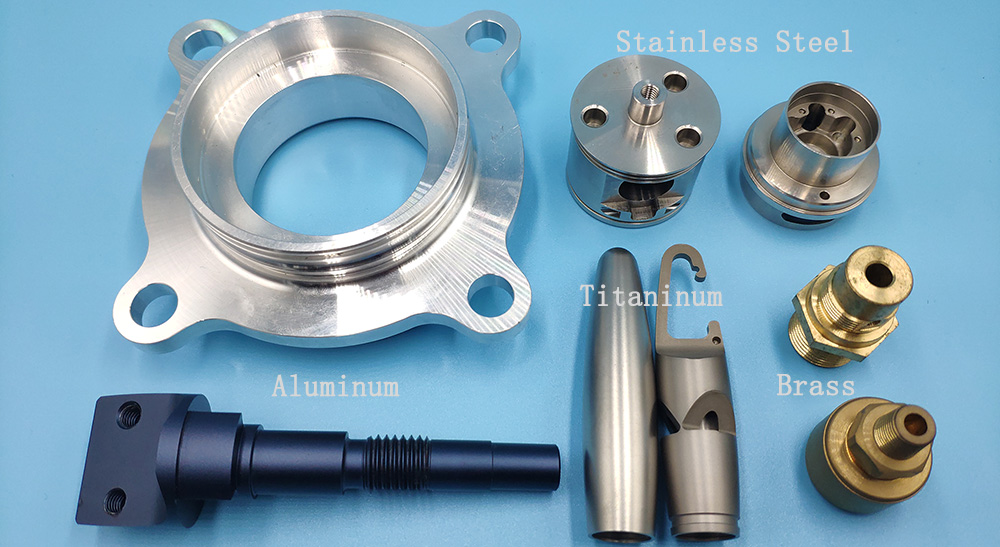

- Metal and plastic part for medical, electronic, consumer, lighting, equipment and more

- Complex structures with high quality

|

5 axes |

Cnc Aluminum Prototype |

Anodized Aluminum Parts |

|

abs precision machining |

Cnc Machinery Parts |

brass cnc turned parts |

|

aluminium milling service |

Brass Spindle |

Product Tags

China Wholesale Cnc Machining Services Near Me Suppliers – CNC Machining Microphone Parts – Anebon Related Video: