China Wholesale Aluminium Stamping Factory – Sheet Metal Fabrication Phone Shell – Anebon

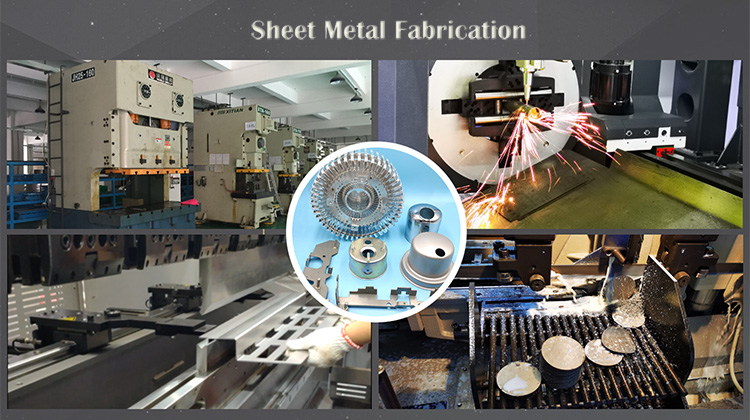

Division I professional production chassis, shield, connectors, heat sink, OA hardware, hardware, household appliances, lighting hardware, automotive hardware, laptops, tablet PCs, one computer, other electronic hardware parts, new energy hardware parts products and provide product service.

Complete mold design manufacturing and processing capacity and complete hardware stamping production line, after the process supporting resources, realize from the mold design, mold making, stamping products, finished product installed a dragon service. Our from the product design, raw material procurement, third-party’s choice to production shipment is the whole process of quality control, and through the PDCA continuous improvement, and constantly improve the quality management and continuous improvement of quality management system, to meet customer requirements.

| Production Material | Brass, Copper, steel, Stainless steel, Steel alloy, Aluminum alloy |

| Surface treatments | Anodize or Nickel plating or as per customer’s requirement |

| Processing methods | Forgings, CNC milling and turning, Grinding, casting, Broaching, etc. |

| Heat treatment capability | Annealing, Normalizing , Nitriding, Tempering ,Carbonitriding, Carburizing and induction hardening |

| Processing machine | CNC machines, Automatic lathe machine, Stamping Lathes, Milling/ Grinding machine, Drilling/ Boring/ Honing machine, Ultrasonic cleaning machine and other advanced production equipments. |

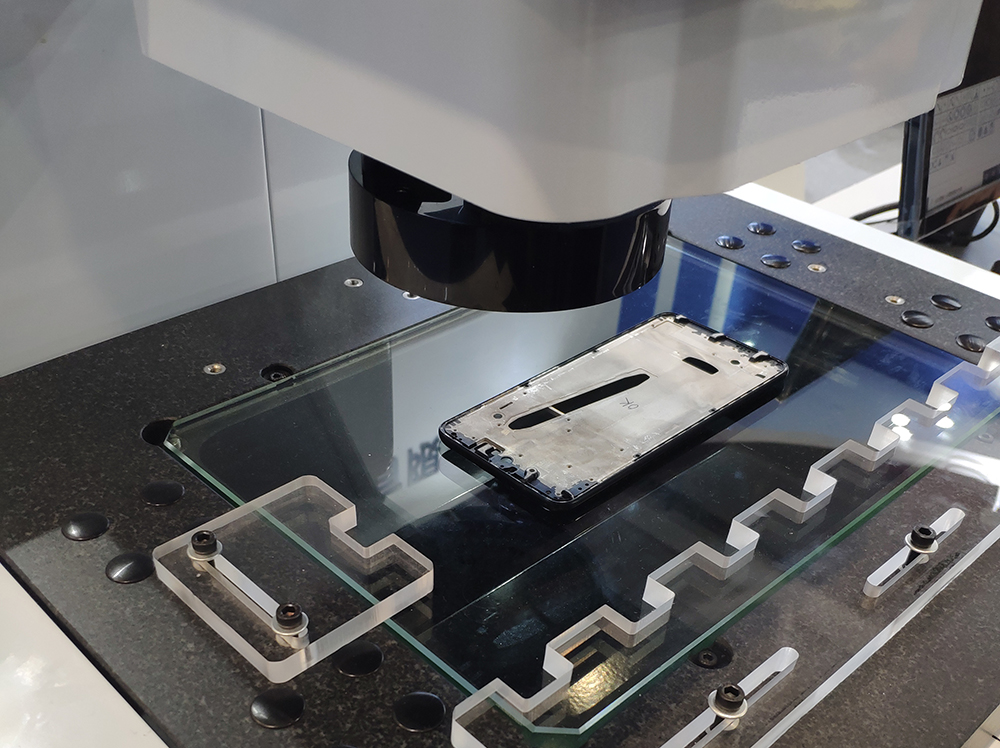

| Inspection machine | Projector, Caliper, Universal testing machine, Surfagauge and screw gauge |

| shipping | 15-18 work days after received order and deposit |

| Payment Terms | T/T or L/C |

| Main Export Markets | North America, Europe, Mid East, Asia, Australia, Central/South America, etc |

| Application | Vehicle, Car, Electronic components, Household, Hardware, etc. |

China Wholesale Aluminium Stamping Factory – Sheet Metal Fabrication Phone Shell – Anebon Related Video: