CNC Machining Titanium

Why choose Anebon?

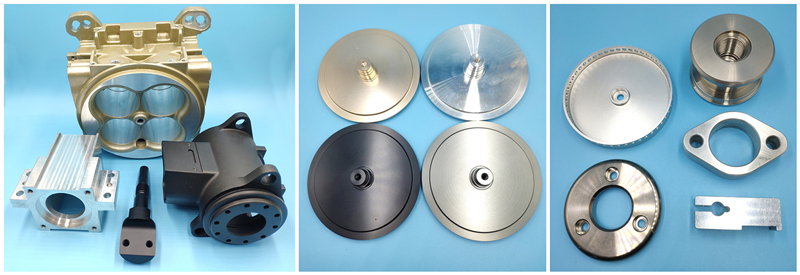

The production difficulty and processing technology of titanium alloy CNC machining parts are very difficult.

Because of the large cutting force, high cutting temperature, small elastic modulus, uneven initial residual stress, CNC machining deformation, difficult processing, and poor surface quality in the CNC machining of titanium alloys.

Anebon uses advanced equipment and high-tech engineers to realize the development and production of highly efficient, stable and lean professional titanium alloy parts.

Processing requirements:

Slower cutting speed

Higher cutting feed rate

Hardware settings

Good coolant flow

Very sharp tool

Avoid feed interruption

Good chip maintenance

| Machining Steel | Cnc Production Machining | 3d Milling |

| Medical Machining | Stainless Steel Cnc Machining | Custom Metal |

| Metal Machining | Amazing Cnc Machining | Cnc Milling Process |

Material Specifications

Titanium’s unique properties make it ideal for demanding applications. Below is a typical composition for Grade 5 titanium (Ti-6Al-4V), widely used in our machining processes:

|

Element |

Percentage (%) |

|---|---|

|

Titanium (Ti) |

88.0–91.0 |

|

Aluminum (Al) |

5.5–6.75 |

|

Vanadium (V) |

3.5–4.5 |

|

Iron (Fe) |

≤0.4 |

|

Oxygen (O) |

≤0.2 |

Applications

Our titanium CNC machining services cater to industries such as:

-

Aerospace: Lightweight, high-strength components like turbine blades and structural fittings.

-

Medical: Biocompatible implants, surgical tools, and prosthetics.

-

Automotive: High-performance parts for racing and luxury vehicles.

-

Marine: Corrosion-resistant fittings for harsh saltwater environments.

Our Team Advantage

Our skilled engineering and technical teams bring extensive experience in CNC machining titanium. From design consultation to production, we collaborate closely with clients to optimize designs for manufacturability, ensuring cost-effectiveness and precision. Our commitment to innovation drives us to adopt the latest machining technologies, keeping us at the forefront of the industry.

Quality Control

As an ISO9001-certified manufacturer, ANEBON implements rigorous quality control at every stage of production. We use advanced inspection tools, including CMM (Coordinate Measuring Machines) and surface profilometers, to verify dimensional accuracy and surface quality. Each CNC machined titanium part undergoes thorough testing to meet client specifications and industry standards.

Packaging and Logistics

Our packaging and logistics solutions ensure safe delivery worldwide. We use custom protective packaging to prevent damage during transit and partner with reliable logistics providers for efficient, trackable shipping.