Machining center programming skills, sharing from CNC technicians!

We usually have three options for drilling cycle selection:

1. G73 (Chip breaking cycle)

Usually used for machining holes more than 3 times the diameter of the bit but not more than the effective edge length of the bit

2. G81 (shallow hole circulation)

It is usually used for drilling center holes, chamfering ,and machining holes up to 3 times the diameter of the drill bit

With the advent of internal cooling tools, this cycle is also used to drill holes to improve processing efficiency

3. G83 (Deep hole circulation)

Usually used for machining deep holes CNC machined

Cooling (outlet water) in machine equipped with spindle center

The cutter also supports center cooling (outlet water) cases

Choosing G81 to process holes is the best choice

The high-pressure coolant will not only take away the heat generated in drilling but will be more timely lubrication cutting edge; high pressure will directly impact chip breaking of a rod, so the tiny chip will also be with high-pressure water discharge hole in time, avoiding the secondary cutting tool wear and processing quality of hole, because there is no cooling, lubrication, the problem of chip removal, So it’s the safest and most efficient solution of the three drilling cycles. aluminum extrusion

The processing material is hard to break chips, but other working conditions are good

The G73 is a good choice because it has no spindle center cooling (water).

This will cycle through the blade’s brief pause time or distance to realize the chip breaker. Still, it would be best if you had a good bit of chip removal ability; a smooth chip removal tank will make scraps discharge faster to avoid the next row of drilling crumbs intertwined, undermining the quality of the hole; using compressed air as auxiliary chip removal is also a good choice.

If the conditions are unstable, the G83 is the safest option.

Deep hole machining will occur because the drill cutting edge can’t timely cool and wears to fas; the depth of the hole of the chip will also be because the relationship is complex to discharge in t; if the chip groove chip blocks the cooling fluid, not only can significantly reduce the service life of the cutter but because the secondary cutting chip would make more rough machining hole wall, thus further cause a vicious cycle.

If the tool is raised to the reference height -R every short distance of -q, it may be suitable for machining near the bottom of the hole, but it will take a lot of time to process the first half of the hole, resulting in unnecessary waste.

Is there a better way? CNC metal machining

Here are two ways of G83 deep hole circulation

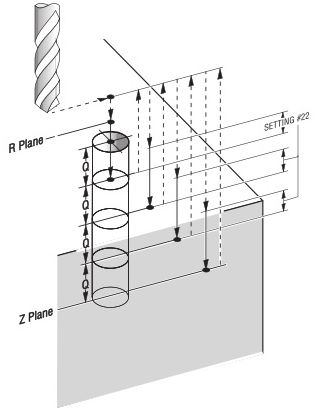

1: G83 X_ Y_ Z_ R_ Q_ F_

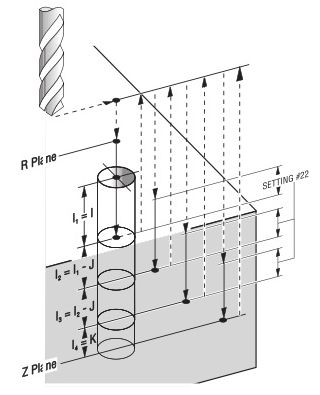

2: G83 X_ Y_ Z_ I_ J_ K_ R_ F_

Firstly, the Q value is a constant value, which means that the same depth is used from the top to the bottom of the hole each time. Due to the need for processing safety, the minimum value is usually selected, which means the lowest metal removal rate, which wastes a lot of processing time virtually.

In the second method, the depth of each cut is denoted by I, J, and K:

When the top of the hole is in good working condition, we can set a larger I value to improve the processing efficiency.; When the middle working condition of the machining hole is general, we gradually decrease the J-value to ensure safety and efficiency. When the working conditions are terrible at the bottom of the machining hole, we set the K value to ensure processing safety.

When used in practice, the second method might make your drilling 50% more efficient and cost nothing!

Anebon Metal Products Limited can provide CNC Machining、Die Casting、Sheet Metal Fabrication service, please feel free to contact us.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com