Importance of Mold Precision And Inspection

As the basic process equipment of industrial production, mold is called “Mother of Industry”. 75% of rough-processed industrial product parts and 50% of fine-processed parts are formed by molds, and most plastic products are also formed by molds. Their quality affects the quality level of the entire processing industry. Stamping molds and injection molds, which account for 80% of mold manufacturing, represent the needs of mold manufacturing and measurement applications to a certain extent.

Anebon meets the diverse needs of users in the mold industry with high-precision, high-efficiency, multi-functional measurement systems and on-site portable measurement technology: accelerate the efficiency of mold manufacturing by improving the level of measurement automation; use software technology to achieve dimensional information integration throughout the manufacturing process Share with.

Stamping

Stamping represented by automobile panel dies have strict requirements on measurement technology in their processing and production, research and integration, trial production, and parts. This includes areas such as the preparation of casting blanks, the processing and testing of complex profiles, mold trial production, and mold clamping analysis.

The large size and weight of the stamping die and the complex shape require the measurement system to be suitable for the harsh conditions of the mold manufacturing site. It has the characteristics of fast acquisition speed, large measurement size, multi-function and portability, and can provide rapid data feedback and evaluation analysis for mold adjustment. The gantry measuring system provides accurate assurance for the quality verification of automobile molds.

Injection mold

The external and internal shapes of the injection molded parts are directly formed by the cavity and core of the injection mold, and have a complex three-dimensional profile. At the same time, the precision and surface quality of the injection mold are required to be high, the precision is required to be 0.01-0.02mm, and the surface roughness is below 0.1um.

Most of the injection molded parts are complete products that are matched with other parts. The shape or dimensional accuracy of the product is very high. After the mold is manufactured, it is necessary to repeatedly try and correct the mold. From mold processing, precision measurement, mold debugging to part measurement, the network composed of on-machine measurement, precision bridge measuring machine and composite image measurement system ensures that everything is perfect. cnc milling part

Checking fixture

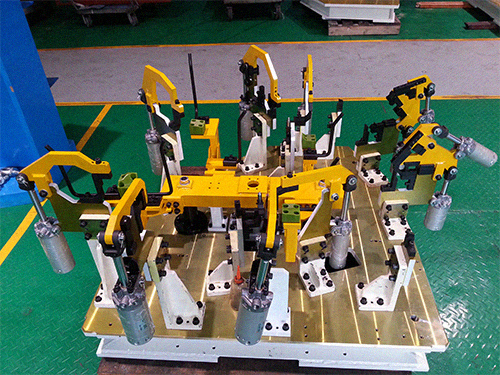

Inspection fixture is the abbreviation of inspection fixture for stamping parts, injection parts and other product parts, and it is an inspection tool specially made according to the specific requirements of the buyer. The size, position and shape of the inspection tool need to undergo strict measurement verification to ensure that it can be used as an inspection benchmark for large quantities of parts on the production line. aluminum part

The flexible and convenient articulated arm measurement system provides advanced on-site measurement methods for the measurement of various tooling, fixtures and inspection tools. Equipped with trigger and scanning probes, the size and position information can be reflected in a timely and fast manner, and accurate shapes can be obtained through data point cloud collection. anodizing aluminum part

Anebon Metal Products Limited can provide CNC machining, die casting, sheet metal machining services, please feel free to contact us.

Tel: +86-769-89802722 Email: info@anebon.com Website: www.anebon.com