High Quality Custom OEM High Precision CNC Machining/Machined/Machine/Milling/Turning/Stamping/Die Casting Metal Aluminum Alloy Auto Spare Machinery Parts

“Quality initial, Honesty as base, Sincere company and mutual profit” is our idea, so that you can create consistently and pursue the excellence for High Quality Custom OEM High Precision CNC Machining/Machined/Machine/Milling/Turning/Stamping/Die Casting Metal Aluminum Alloy Auto Spare Machinery Parts, We welcome new and previous customers from all walks of lifestyle to contact us for long run organization relationships and mutual achievements.

“Quality initial, Honesty as base, Sincere company and mutual profit” is our idea, so that you can create consistently and pursue the excellence for China Machinery Part and Machining Parts, We always stick to the tenet of “sincerity, high quality, high efficiency, innovation”. With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our merchandise, and we have been sure that we’ll supply just what you want, as we always believe that your satisfaction is our success.

Product Detail:

Key Specifications/Special Features:

Materials: carbon steel, stainless steel, brass, copper, alloy steel

Finish: plain, black phosphated, white/ yellow/ black zinc plated.

Package: carton/ pallet , small box/ carton/pallet or customer request.

Diameter: 8mmxm6-1.0×25 8mmxm6-1.0×27 8mmxm6-1.0×29 8mmxm6-1.0×31

8mmxm6-1.0×37 6mmxm4-1.0×25 6mmxm4-1.0×27 6mmxm4-1.0×29 6mmxm4-1.

Standards: DIN, ANSI, JIS, BS, GB, ISO and GB.

Customized designs are welcome

OEM/ ODM are welcome

Primary Competitive Advantages:

Experienced Staff, Green Product, Guarantee/Warranty, International Approvals

Product Features, Product Performance, Prompt Delivery, Quality Approvals

Reputation, Service

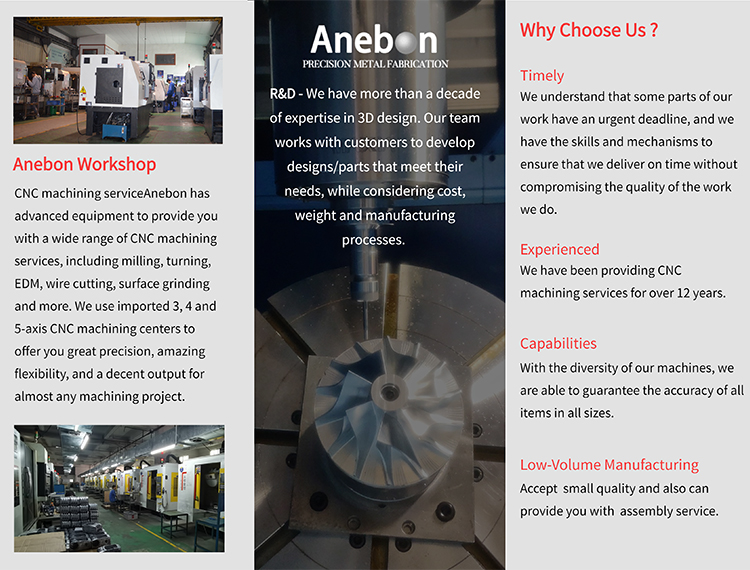

We provide CNC Machining Metal parts use for all terrain vehicle:

1) Medical equipment parts

2) Electric/electronic equipment parts

3) Other machined parts

FAQ

1:What material can be processed ?

Copper alloy ,aluminium ,Stainless steel (SUS303/SUS304/SUS420F) ,Gcr15,45# ,3Cr13 ,4Cr13 ,DSR7B and so on

2:What are the processing methods ?

Cutting ,Turning processing, Milling processing, WEDM, grinding process, heat treatment processing, polishing and stretch .

3:How long will the sample production cycle take ?

3 days production 7 days delivery.

4:What’s the way of delivery ?

1.Less weight products use international express delivery.

2.Heavy products use shipping

5:What are the terms of payment ?

L/C T/T M/T D/D

High Quality Custom OEM High Precision CNC Machining/Machined/Machine/Milling/Turning/Stamping/Die Casting Metal Aluminum Alloy Auto Spare Machinery Parts Related Video: